Home » Brick Making Machine » Hydraulic Brick Making Machine

Hydraulic Brick Making Machine

The hydraulic brick machine mainly uses fly ash, river sand, mineral powder, slag, stone powder, coal slag, coal gangue, tailing slag, chemical slag, etc. as the main raw materials. It can make non-burning bricks, refractory bricks, porous bricks, colored pavement bricks, etc.

The hydraulic brick making machine takes hydraulic transmission as the production power and adopts PLC control system to realize the integration of machine, electricity and hydraulic, and automatic cycle work.

Our equipment adopts high and low pumps and filling valves to improve the molding speed, and can be stacked after molding with low noise, which reduces the space and saves labor. The hydraulic block making machine automatically feeds the material, and the automatic distribution speed is fast. It can be pressed and formed without vibration, and the finished product has high accuracy.

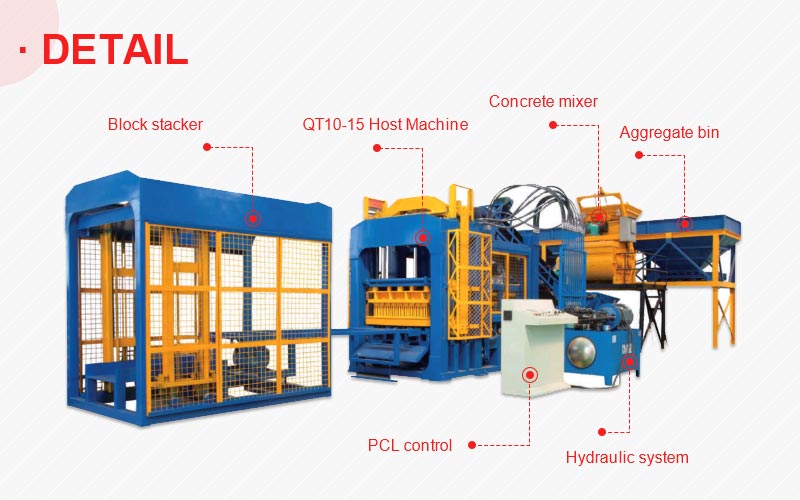

The composition of hydraulic brick machine

The hydraulic brick machine consists of the main machine of the brick machine, the motor, the PLC control system, the hydraulic system, the pneumatic system, the stacker and the mixer to form a fully automatic production line. Through the optimized design program, with the preferred hydraulic, electrical, and components, the various parts are connected to realize the automation of the entire production process.

The automatic hydraulic brick making machine is composed of three parts: the main engine, the hydraulic system and the control system. The main equipment includes the frame, the main cylinder, the ejector cylinder and the liquid filling device. The hydraulic system consists of a fuel tank, a high-pressure pump, a low-pressure control system, an electric motor, and various pressure valves and directional valves. Under the control of the electrical system, the energy conversion is realized through the hydraulic pump, the oil cylinder and various hydraulic valves, and the cyclic operation of each operation action is realized.

Working principle of hydraulic brick making machine

After the raw materials are weighed by the batching machine, they are sent into the mixer by the belt conveyor. The PLC controller operates to pour the material into the distributing machine, and the vibration is even. Then the hydraulic cylinder outputs force, and the upper and lower molds press the material to form the brick body. Then the formed bricks are pushed out, and the palletizer stacks the bricks into stacks. The work of the fixed brick machine production line is controlled by the data control system throughout the process, with easy operation, high production efficiency and accurate product specifications.

The fully automatic hydraulic hollow block machine is designed based on the working principle of Pascal, and uses hydraulic oil pressure transmission to realize the pressing and forming of brick blanks.

Classification of hydraulic brick machines

Stationary brick making machine

The hydraulic brick making machines produced by our Daswell machinery are mainly fixed BMM4-15, BMM6-15, BMM8-15, BMM10-15 and BMM12-15 models.

The BMM15 series hydraulic brick making machine has superior performance, high efficiency and low energy consumption. It is our best-selling and best quality hydraulic brick making machine series. It is an economical and applicable equipment, which can meet the diversified production needs of the brick making industry, and is cost-effective. It can produce various blocks such as exterior wall blocks, interior wall blocks, floor blocks, berm blocks, interlocking pavement blocks and curb stones. The secondary cloth structure can also produce colored pavement bricks.

The body of the hydraulic cement brick making machine is made of high-strength castings and welding of special materials, with good rigidity, vibration resistance and long service life.

Mobile brick making machine

In addition to BMM15 series brick machine, we also have QMJ series large mobile hydraulic egg laying brick machine.

This series of hydraulic movable brick making machine is also our best seller. This series of mobile hydraulic brick making machine is a walking hydraulic brick making machine developed and produced by our company on the basis of foreign advanced technology. It has the following advantages: advanced design, reasonable structure and high technical content.

The cement bricks hydraulic machine adopts moulding box vibration, hydraulic stripper, electric walking function, it can move forward, backward, turn and other advanced technologies and functions. QMJ-6A and QMJ-10 A have a silo and are mechanical fabrics, which are faster. This series of models is small in size, large in output, easy to operate, low in energy consumption and high in efficiency.

Hydraulic Brick Making Machine vs. Ordinary small Brick Making Machine

Features of hydraulic brick machine:

- The automatic hydraulic brick making machine has high forming pressure, which improves the quality of bricks. The density and strength of bricks are high, and the breakage rate of bricks also decreases during transportation.

- The hydraulic brick machine has a high degree of automation. Less labor, no need for workers to send raw materials. The equipment can work continuously without stopping the stacking. Greatly reduces the labor intensity of workers. Labor saving, labor saving, high output.

- The hydraulic brick making machine for sale adopts the step-by-step pressurization and multiple exhaust process, and the four-time pressurization and three-time exhaust process are used in the pressing process. The air contained in the powder is smoothly discharged during the pressing process, which makes the bricks have high strength and is not prone to cracks, and the product quality is high.

- The hydraulic brick machine has low production noise and low damage to the machine. The hydraulic non-burning brick machine is equipped with a pneumatic shock absorption system. The system can greatly reduce noise and vibration, make the equipment more stable and have a longer life.

Ordinary small brick machine features:

- Small size and low power, the corresponding output will be lower.

- The hydraulic press brick making machine structure is simple, the degree of automation is relatively low, and it is relatively labor-intensive.

- When working, it is vibrated by three vibration motors, and the noise is relatively large.

- The density of the bricks produced is low, and the hardness needs to be dried for a period of time to meet the required requirements, and the manufacturing cycle is long.

Technical Data:

Automatic brick making machine

| Model | BMM4-15 | BMM6-15 | BMM8-15 | BMM10-15 | BMM12-15 |

| Capacity (for 390x190x190mm hollow block) (pcs/h) | 720-960 | 1080-1440 | 1200-1600 | 1440-1800 | 1728-2160 |

| Capacity (for 240x115x53mm solid brick) (pcs/h) | 5930-6720 | 7680-8861 | 9000-10000 | 11011-12480 | 12700-14400 |

| Overall Dimension (mm) | 7310X2500X2810 | 7450x2450x3050 | 8300X2800X2900 | 9350X3000X2900 | 9350x3200x2900 |

| Rated pressure (Mpa) | 16 | 16 | 21 | 21 | 21 |

| Main vibration form | Platform vibration | Platform vibration | Platform vibration | Platform vibration | Platform vibration |

| Vibration frequency (rpm) | 4600 | 4500-5100 | 2800-4500 | 2800-4500 | 2800-4500 |

| Pallet size (mm) | 1020X570 | 850×680 | 950X900 | 1100X900 | 1300×900 |

| Exciting force (KN) | 55 | 65 | 85 | 110 | 110 |

| Overall power (KW) | 27.5 | 28 | 51 | 67 | 67 |

Semi-automatic brick machine

| Model | BMM4-40B | BMM4-26 |

| Capacity(for 390×190×190mm hollow brick) (pcs/h) | 250-312 | 480-576 |

| Molding Cycle (s) | 40 | 26 |

| Vibration Frequency (rpm) | 2800 | 4200 |

| Exciting Force (KN) | 40 | 45 |

| Power (kw) | 9.3 | 11.6 |

| Overall Dimension (mm) | 1500×1750×1900 | 2150×1660×2550 |

| Pallet Size (mm) | 850×450 | 850×450 |