Hollow Brick Making Machine

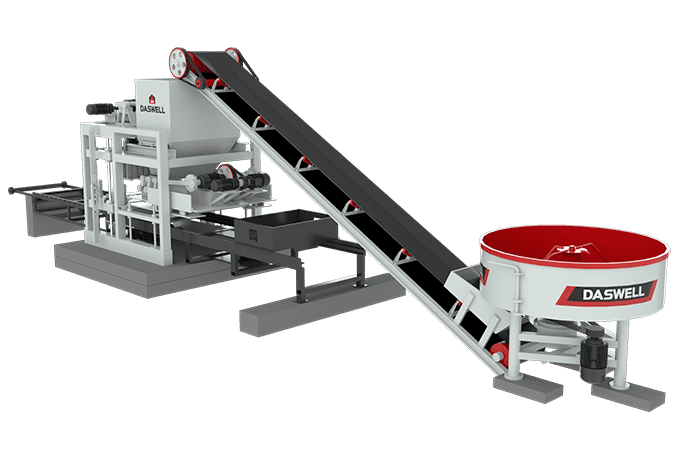

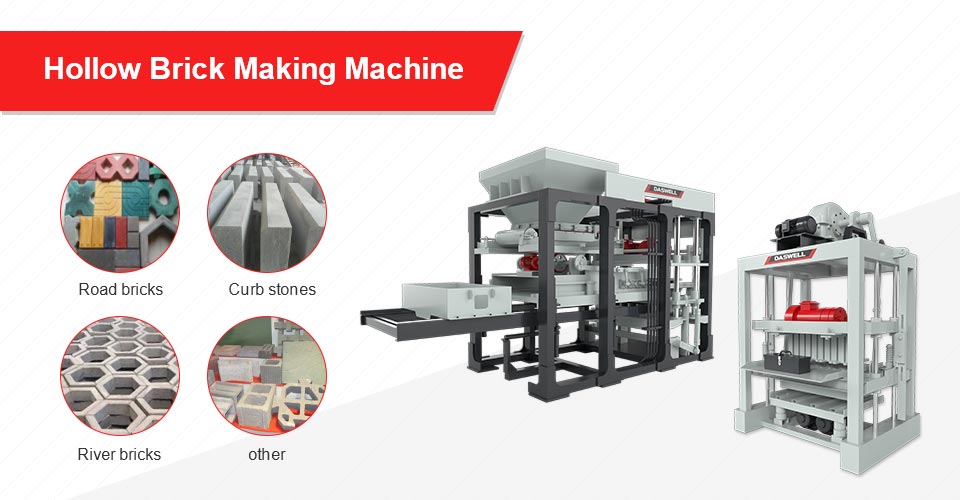

Daswell hollow brick making machine is suitable for the fixed production of various specifications of standard bricks, hollow blocks, porous bricks and other concrete products. It is widely used in buildings, roads, squares, hydraulic works, gardens and other constructions.

What is a hollow brick making machine?

The hollow blocks machine is compatible with various brick molds such as road bricks, roadside stones, and river bricks. The upper part of the machine is a waterproof vibration motor, and the lower part is the vibration excitation platform. The hollow brick making machine can automatically feed the board, automatically feed, 360° automatic distribution, automatic demoulding, automatic brick output, and automatic stacking. At the same time, the hollow blocks maker machine can choose the horizontal secondary cloth system to increase the color effect. It adopts a special storage and distribution device to prevent the premature liquefaction of concrete and ensure the quality of the finished product.

Features of hollow brick making machine

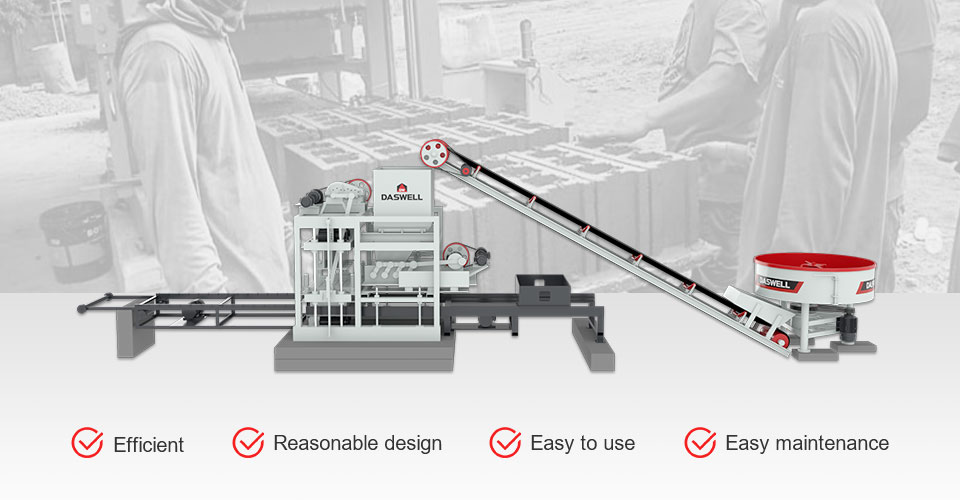

Daswell hollow blocks machine for sale is characterized by high efficiency, reasonable design, simple operation and convenient maintenance. The block forming is mainly by hydraulic and mechanical, and the vibration pressure is completed. It can realize automatic operation, which greatly reduces the labor intensity of operators. The performance of each unit is well coordinated, and it is suitable for producing different proportions and different types of blocks. This model can be used to produce standard bricks, hollow bricks, porous bricks, etc. It can meet the needs of hollow bricks making in different markets.

How to choose a hollow brick machine?

When choosing a hollow bricks machine, you should pay attention to the following points:

First of all, it is necessary to choose equipment consumers with excellent quality and reputation. Secondly, go to the factory for on-the-spot investigation before purchasing, and find out the materials and parts used by the equipment manufacturer in the manufacturing process. To ensure the quality of the accessories of the hydraulic hollow block machine, such as the stiffness, quality of steel, motor, oil cylinder and PLC control system, etc. Finally, when choosing a hollow brick machine, try to choose a model with a large number of moldings at one time. This is because the number of forming of the brick machine at one time will directly affect the output of the brick factory.

Hollow brick making machine production process:

- 1. Batching system. Using computer control, different raw materials can be selected according to the selection. Automatic metering can be performed, and then the material is transferred into the mixer.

- 2. Mixing system. It is suitable for forced mixing of various materials, and the mixed materials are sent to the hollow block molding machine by the conveyor.

- 3. The concrete hollow blocks machine is intelligently controlled by PLC computer, and adopts hydraulic transmission and vibration pressure molding. Computer control can adjust parameters according to the needs of producing different products and materials. The random monitoring function has automatic fault prompting and man-machine dialogue. According to the user’s production requirements, different types and specifications of molds can be selected.

- 4. Lifting plate system. The mechanical synchronous transmission is adopted by the automatic hollow brick machine, and the product is stably lifted. Controlled by the PLC main computer, the formed brick products are raised to a certain height.

- 5. Brick machine finger cart system. It consists of two devices. On the track, it travels back and forth between the lifting and lowering machine and the curing kiln, and transports the newly formed and cured brick products.

- 6. Drop plate and palletizing system. The brick machine finger cart takes out the product from the curing kiln for curing and send it to the lowering machine. It is then palletized by the lowering machine. Finally, the brick products are transported by forklift to the finished product yard.

FAQ

1. Q: How to determine the brick machine model?

a. How many bricks need to be produced in a day?

b. What are the dimensions of the bricks?

c. Hollow brick or solid brick?

2. Q: How to install the hollow block manufacturing machine?

A: The installation of the small brick machine is relatively simple, and the customer can install it by himself. If you have any questions, we can guide you online. For large brick machines, we can send engineers to the customer site to guide the installation. The client is responsible for the engineer’s round-trip air tickets, accommodation, visa fees, etc. And pay each engineer $150 a day.

3. Q: How many sets of moulds does a set of brick making machine match?

A: A set of hollow bricks manufacturing machine is equipped with a set of molds for free. Customers can also buy other molds if they need them, but they need to be charged additionally.

4. Q: What does a set of BMM4-26 brick machine include?

A: A set of BMM4-26 automatic hollow block making machine includes brick machine, JQ500 mixer, a belt conveyor, a palletizer and some other accessories. Mixers and palletizers are optional, and customers can prepare them by themselves.

5. Q: What kind of bricks can your brick machines produce?

A: Can produce all kinds of hollow bricks, solid bricks, paving bricks. Basically all of the above can be produced.

Technical Data:

Automatic brick making machine

| Model | BMM4-15 | BMM6-15 | BMM8-15 | BMM10-15 | BMM12-15 |

| Capacity (for 390x190x190mm hollow block) (pcs/h) | 720-960 | 1080-1440 | 1200-1600 | 1440-1800 | 1728-2160 |

| Capacity (for 240x115x53mm solid brick) (pcs/h) | 5930-6720 | 7680-8861 | 9000-10000 | 11011-12480 | 12700-14400 |

| Overall Dimension (mm) | 7310X2500X2810 | 7450x2450x3050 | 8300X2800X2900 | 9350X3000X2900 | 9350x3200x2900 |

| Rated pressure (Mpa) | 16 | 16 | 21 | 21 | 21 |

| Main vibration form | Platform vibration | Platform vibration | Platform vibration | Platform vibration | Platform vibration |

| Vibration frequency (rpm) | 4600 | 4500-5100 | 2800-4500 | 2800-4500 | 2800-4500 |

| Pallet size (mm) | 1020X570 | 850×680 | 950X900 | 1100X900 | 1300×900 |

| Exciting force (KN) | 55 | 65 | 85 | 110 | 110 |

| Overall power (KW) | 27.5 | 28 | 51 | 67 | 67 |

Semi-automatic brick machine

| Model | BMM4-40B | BMM4-26 |

| Capacity(for 390×190×190mm hollow brick) (pcs/h) | 250-312 | 480-576 |

| Molding Cycle (s) | 40 | 26 |

| Vibration Frequency (rpm) | 2800 | 4200 |

| Exciting Force (KN) | 40 | 45 |

| Power (kw) | 9.3 | 11.6 |

| Overall Dimension (mm) | 1500×1750×1900 | 2150×1660×2550 |

| Pallet Size (mm) | 850×450 | 850×450 |