Everything You Should Know about Concrete

What is concrete?

Concrete is a general term for engineering composite materials in which aggregates are cemented into a whole by cementitious materials. The concrete we usually say refers to the cement concrete obtained by using cement as cementitious material, sand and stone as aggregate, together with water (if necessary, admixtures can be added), and mixed together in a certain proportion, also known as ordinary concrete. It is widely used in civil engineering.

Concrete has the characteristics of abundant raw materials, low price and simple production process. Therefore, in recent years, the amount of concrete used in the world has been increasing. At the same time, it also has the advantages of high compressive strength, good durability and wide application range.

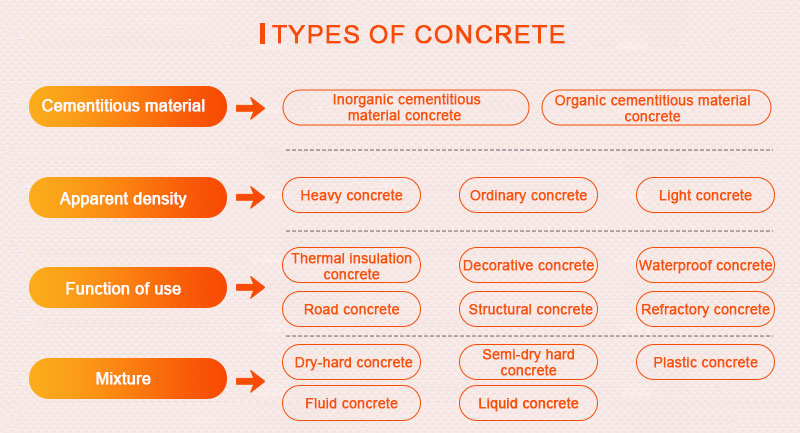

Types of concrete

According to the cementitious material, concrete can be divided into inorganic cementitious material concrete and organic cementitious material concrete.

What is a cementitious material? In construction materials, any material that has undergone a series of physical and chemical actions by itself, or has undergone a series of physical and chemical actions after being mixed with other substances (such as water), can change from a slurry to a hard solid, and can glue loose particles of material (such as sand, stone) or block materials (such as bricks) into a whole, which is called cementitious material.

According to the apparent density, concrete can be divided into heavy concrete, ordinary concrete and light concrete. The difference between these three types of concrete lies in the aggregates.

Heavy concrete is an apparent density greater than 2500 kg/m3 and is made of particularly dense and exceptionally heavy aggregates. Ordinary concrete, which is the concrete we commonly use in construction, has an apparent density of 1950 to 2500 kg/m3. It is mainly prepared with sand and stone as the main aggregate. Light concrete has an apparent density of less than 1950 kg/m3.

According to the function of use, concrete can be divided into thermal insulation concrete, decorative concrete, waterproof concrete, road concrete, structural concrete, refractory concrete, etc.

According to the mixture, concrete can be divided into dry-hard concrete, semi-dry hard concrete, plastic concrete, fluid concrete, etc. Mixtures generally refer to freshly mixed concrete. Fresh mixed concrete refers to the concrete that has not yet hardened, which is uniformly mixed with various materials in a certain proportion, also known as concrete mixture.

What is concrete made of?

The concrete we often say is generally cement concrete, which is made up of cement, aggregate, water and admixtures.

Cement

Cement plays a cementing role in concrete. The choice of its variety and quantity directly affects the strength, workability, durability and economy of concrete. Therefore, when preparing concrete, the appropriate cement type and strength grade should be selected.

The selection of cement types should be comprehensively considered according to project characteristics, environmental conditions, construction conditions and the situation of cement suppliers.

The choice of cement strength grade should be adapted to the strength grade of concrete. The higher the strength grade of concrete, the higher the selected cement strength grade. Conversely, the lower the strength grade of concrete, the lower the selected cement strength grade.

Aggregate

Aggregates can be divided into coarse aggregates and fine aggregates. Aggregates with a particle size larger than 4.75mm are called coarse aggregates, that is, stones. Aggregate with a particle size of less than 4.75mm is called fine aggregate, that is, sand. Sand also includes natural sand and artificial sand.

Sand aggregates account for more than eighty percent of the total volume of concrete. It generally does not chemically interact with cement and acts as an overall skeleton in concrete.

Cement, sand, and water form cement mortar, which wraps on the surface of coarse aggregates and fills the gaps between the aggregates, and plays a lubricating role before hardening, so that the concrete mixture has good fluidity and plasticity, which is convenient for construction. After the cement mortar hardens, it cements the aggregates together, creating strength and forming a solid whole.

Water

The water used for mixing concrete is usually clean fresh water with a PH value of not less than 4, such as tap water that can be used for people to drink, river water, well water, lake water, etc.

Mixing concrete with water containing harmful substances will affect the workability and setting speed of concrete, hinder the development of concrete strength, reduce the durability of concrete, and accelerate the corrosion of steel bars.

Admixtures

Admixtures are substances added during concrete mixing to improve concrete properties.

Commonly used admixtures are: water reducing admixture, air entraining admixture, early strength agent, retarder, accelerator, anti-freezing agent, etc.

When selecting admixtures, it needs to be determined according to the actual situation of the project. For example, if you want to produce impermeable concrete or frost-resistant concrete, you can choose an air entraining admixture or a water reducing admixture.

What machine is used to produce concrete?

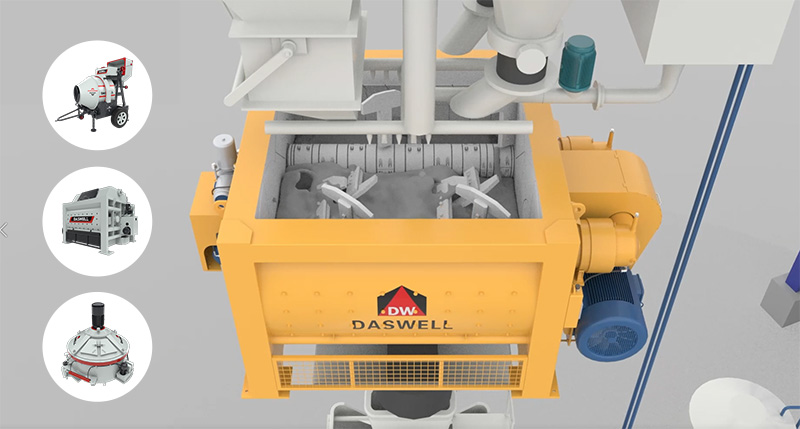

At present, the main equipment for producing concrete is concrete mixer machine. It can mix concrete alone, or form a concrete mixing plant for mass production together with the aggregate batching machine, cement silo and other supporting equipment.

There are many different types of concrete mixers, the common ones are drum concrete mixers, twin shaft concrete mixers, planetary concrete mixers, etc.

Drum concrete mixers are also known as self-falling mixers. There is no stirring blade on the inner wall of the mixing drum, but mainly through the rotation of the tank, after the materials are lifted to a certain height, the materials are free to fall by the action of gravity to complete the mixing.

Twin shaft mixers and planetary mixers are also known as compulsory concrete mixers. The tank body of this type of mixer does not rotate, but there are stirring blades in its mixing cylinder, so as to complete the forced mixing of the materials.

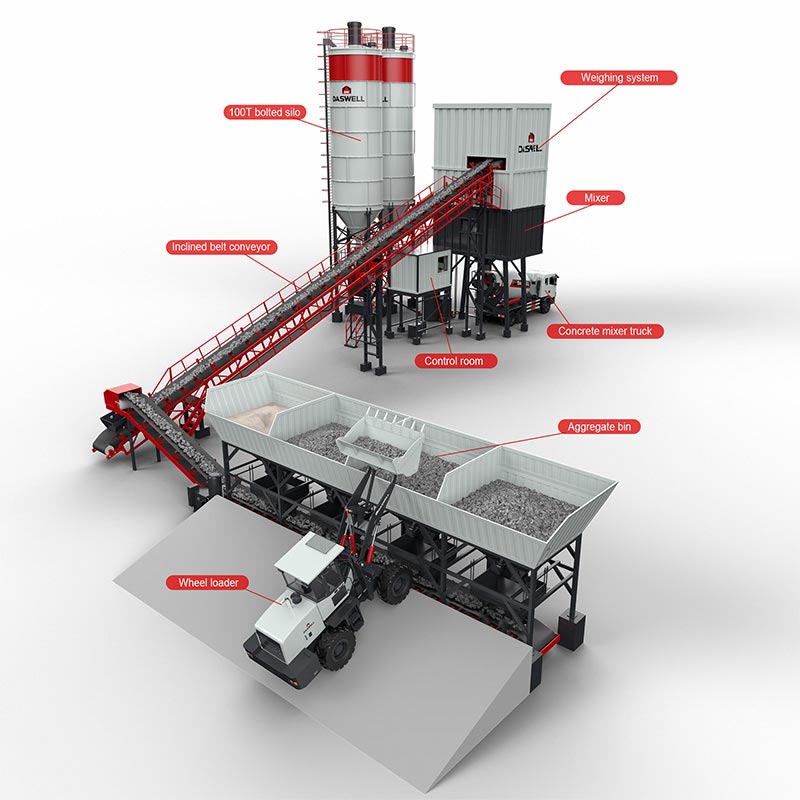

According to whether it is movable or not, concrete mixing plant is divided into stationary type plant and mobile type plant. Its main components are aggregate batching machine, belt conveyor, mixer machine, cement silo, control room, etc. The commonly used mixer machine on the concrete mixing plant is twin shaft concrete mixer.

How concrete is made?

Let’s take a concrete batching plant as an example to briefly describe the production process of concrete.

The process of producing concrete in a batching plant can be simply summarized as weighing – conveying – mixing.

The loader feeds different aggregates (sand, stones, etc.) into the storage bin of the corresponding batching machine, and then enters the weighing hopper for weighing. The weighed aggregate is lifted to the top of the mixer through a belt conveyor or a lifting hopper to wait for feeding.

At the same time, the cement in the cement silo is transported by the screw conveyor to the cement weighing hopper above the mixer for measurement. The water and the admixture are respectively transported to the water weighing hopper and the admixture weighing hopper through the pipeline for measurement.

The aggregate, cement, admixture and water that have been measured are discharged into the mixer for mixing in turn. After the mixing is completed, the discharge door of the mixer is opened, and the finished concrete is discharged into the concrete mixer truck. Finally, the concrete is delivered to the construction site by a concrete mixer truck.

The whole process is controlled by a fully automatic PLC control system, which is simple and convenient to operate, and also ensures the high efficiency and precision of production.

If you want to know more about concrete, welcome to get in touch with us!