Understanding Heavy Calcium Carbonate from Six Perspectives

What is ground calcium carbonate?

Ground calcium carbonate is a kind of white powder obtained by physical methods from calcite, limestone, dolomite, chalk, shells, etc. Its appearance is gray-white or dark brown granular solid, slightly acidic, with high purity and stable composition. It is a very important chemical raw material, widely used in industry, and is one of the commonly used fillers.

Raw material for ground calcium carbonate powder production

Limestone

The calcium carbonate deposited in the lake and sea, after losing water, is compressed and cemented to form a rock called limestone. Its Mohs hardness is less than 3, which is a medium hardness ore. In Egypt, Pakistan and other countries have a large number of mineral deposits. Therefore, the production of heavy calcium carbonate in these two countries mostly uses limestone as a raw material.

Calcite

Calcite is also a calcium carbonate mineral, which is most commonly found in natural calcium carbonates. Therefore, calcite is a widely distributed mineral. Calcite has a variety of crystal shapes. Their aggregates can be clusters of crystals, or granular, massive, fibrous, stalactite, earthy, and so on.

Marble

Its main component is calcium carbonate, accounting for more than 50%. It comes in many colors and usually has a distinct pattern. The Mohs hardness is between 2.5 and 5. Because it has various colors and is very beautiful after polishing, it is also often used as a decorative material in the construction industry.

ChalkChalk is a fine deposit of calcium carbonate, a variant of calcite. Originally formed deep in the ocean floor through the compression of tiny plankton that settled to the seafloor. The world-famous origins include Essex County, New York, USA and Jiangxi Province, China.

What is ground calcium carbonate powder used for?

Rubber industryAdding heavy calcium carbonate to rubber can increase the volume of the product, which can save expensive natural rubber and greatly reduce production costs. Moreover, the tensile strength, tear strength and wear resistance of the treated rubber are better than those of pure rubber.

Plastic industry

Excellent results can be obtained by using ground calcium carbonate as a filler. ①Increase production and reduce costs. ②Improve the heat resistance of plastic products. ③Improve the color of the finished product.

Paper industry

The paper industry is the largest application field of heavy calcium carbonate. It can replace wood pulp and other pigments, which can ensure the whiteness and strength of paper with low cost.

Coating industryGround calcium carbonate has high whiteness and low oil absorption. It can reduce the amount of emulsion required and reduce the cost of latex paint. It can also improve the performance of the coating.

Construction industryHeavy calcium carbonate powder is the main ingredient in concrete for construction. This reduces production costs and increases the toughness and strength of concrete.

Fireproof ceiling industryHeavy calcium is also used in the production of fireproof ceilings. It can not only improve the whiteness and brightness of the product, but also increase the fire resistance of the product.

Feed industryGround calcium carbonate can increase the calcium content in the feed, thereby improving the quality of the feed.

What is difference between GCC and PCC?

The full name of GCC is Ground Calcium Carbonate. The full name of PCC is Precipitated Calcium Carbonate. Although both belong to calcium carbonate, there are many differences. Next, a specific analysis will be carried out from five aspects: production method, bulk density, whiteness, moisture content, and price.

Production methodGCC is mainly powder obtained by grinding natural minerals such as calcite, marble, limestone, and chalk as raw materials by grinding equipment.PCC is mainly powder obtained from limestone as raw material through calcination, digestion, carbonization, dehydration, drying, classification and other processes.

Bulk densityThe difference in product bulk density is the most obvious difference between GCC and PCC. The bulk density of ground calcium carbonate products is relatively large, generally 0.8-1.3g/cm³; the bulk density of precipitated calcium carbonate products is relatively small, generally 0.5-0.7g/cm³. The bulk density of some nano calcium carbonate products can even reach about 0.28g/cm³.

WhitenessGCC has relatively more impurities, so the whiteness of the product is generally 89% to 93%, and a very small number of products can reach 95%.PCC products have high purity, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97%.

Moisture contentThe moisture content of ground calcium carbonate products is generally 0.2% to 0.3%. The moisture content is relatively low and at the same time relatively stable. Ordinary precipitated calcium carbonate products have a moisture content of 0.3% to 0.8%, and sometimes fluctuate to a certain extent, which is not very stable.

PriceThe processing of heavy calcium carbonate is mainly achieved by physical methods of mechanical crushing and grinding. The production of light calcium carbonate is obtained by chemical reaction precipitation.The latter process is much more complicated than the former, and the requirements are correspondingly stricter. Therefore, GCC with the same particle size is about 30% cheaper than PCC. If performance allows, most buyers will choose to buy ground calcium carbonate. Therefore, the market prospect of ground calcium carbonate is very broad.

How ground calcium carbonate is produced?

There are two main production methods of heavy calcium carbonate powder: dry method and wet method. Ground calcium powder below 2500 mesh is generally dry ground. The production of ultra fine ground calcium carbonate over 2500 mesh is mainly by wet grinding.

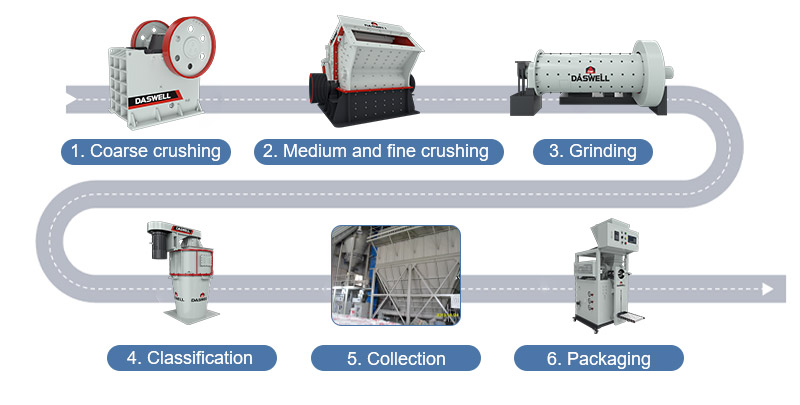

Dry grinding is a relatively common method at present, and the technology is relatively mature. Generally, a processing system composed of crushing equipment, grinding equipment and classification equipment can be used to obtain products of various particle sizes. The following figure is the specific process.

The wet grinding process is more complex and requires additional grinding aids. This makes it possible to obtain particles with better dispersibility and finer particle size. Compared with the dry method, the production cost of the wet method will also be higher. The general wet grinding process is shown below for you.

Precautions for storage of ground calcium carbonate powder

Moisture proofBecause heavy calcium carbonate is a powder, it absorbs water more. Therefore, it is essential to do a good job of moisture-proof work.

Away from acidic substancesSince heavy calcium powder is calcium carbonate, avoid storing it with acidic substances. Because the two are likely to have a chemical reaction, affecting the efficacy of heavy calcium powder.

Avoid high temperatureIn the case of high temperature, heavy calcium powder is easy to decompose, which will reduce the effect of heavy calcium. Therefore, the finished ground calcium carbonate powder should be placed in an area out of direct sunlight.