27 Tools Every Concrete Contractors Might Need

In order to complete each project with high efficiency and high quality, every concrete contractor needs to have a complete set of equipment. Whether it is the early site preparation stage, the production stage, or the later stage of concrete pouring and finishing, it is necessary to have corresponding equipment to assist in the completion of the corresponding work.

For frequently used tools, you might consider purchasing a new device. For some equipment that is more expensive but not used frequently, you can also choose to rent one when you need to use it. So, the following article will introduce you to 27 types of equipment that a concrete contractor may need.

Protective gear

In order to ensure the safety of the construction workers, they need to wear the appropriate protective gear before the construction begins.

1.Gloves

During the construction process, most of the work requires the use of hands. And some of the ingredients in concrete may cause some irritation to the skin, so wearing gloves can prevent concrete from causing damage to the hands. And gloves can also prevent hands from being exposed for a long time and rubbing to blistering.

2.Rubber boots

Similar to gloves, rubber boots protect workers’ feet from direct contact with concrete. At the same time, even if the rubber boots are stained with concrete, it is easy to clean.

3.Safety glasses

Safety glasses are standard equipment on most construction sites. They protect your eyes from dust and debris when grinding, drilling, sawing or troweling concrete.

Tools for site preparation

4.Laser level

The application of laser level not only can accurately control the elevation of concrete slab and improve the quality of the project, but also can control the thickness of concrete slab and reduce the consumption of concrete.

5.Compactors and tampers

The compactors and tampers is a kind of compaction machine that utilizes impact and vibration to ram backfill soil layer by layer. It is mostly used for compacting and leveling the foundation during construction, making the foundation more solid and firm.

6.Vapor barriers

A vapor barrier is a layer of material placed to prevent moisture from the soil below ground level from penetrating into the concrete slab. But a vapor barrier is not necessary for every concrete project.

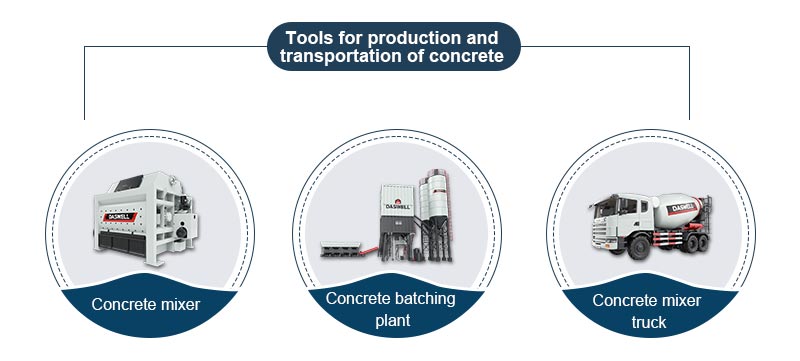

Tools for production and transportation of concrete

7.Concrete mixer

Concrete mixer is mainly used to produce concrete. Depending on the working principle, it includes forced mixers and self-falling mixers. Choose the right type for your project.

8.Concrete batching plant

The concrete batching plant meets the needs of customers for mass production of concrete. It is composed of aggregate batching machine, belt conveyor, concrete mixer, cement silo, control room and other parts, with high automation and good production quality.

9.Concrete mixer truck

The function of the concrete mixer truck is mainly to transport the produced concrete to the construction site. During transportation, the mixing tank of the truck will keep rotating to prevent the transported concrete from solidifying.

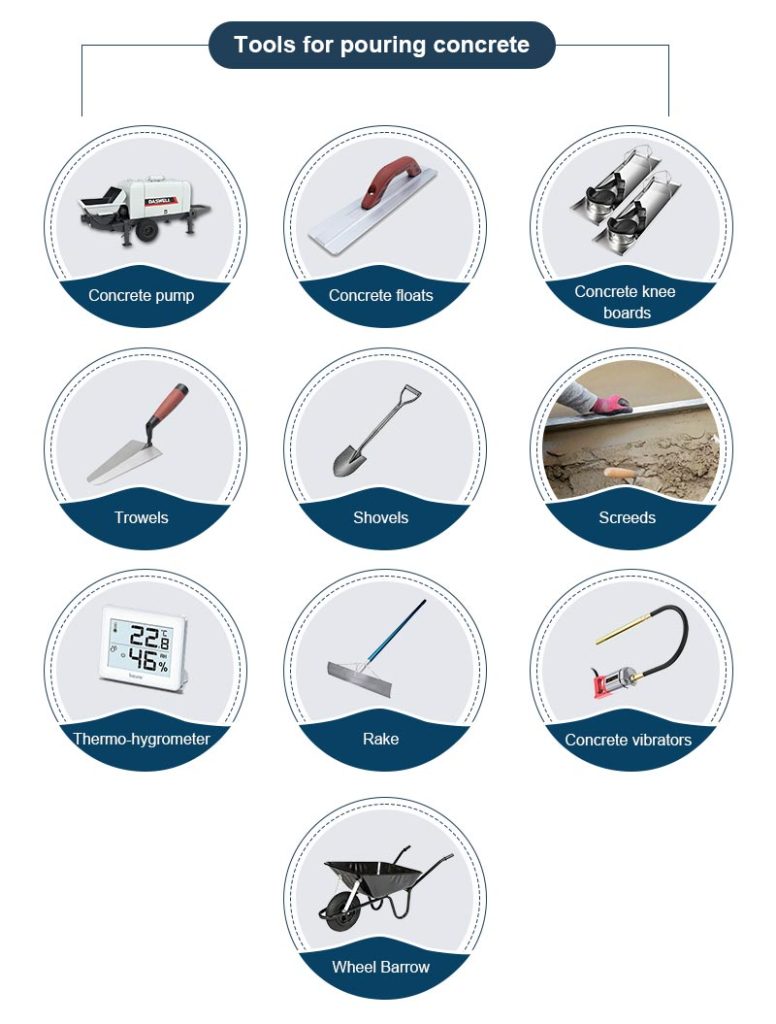

Tools for pouring concrete

10.Concrete pump

A concrete pump is a device that uses pressure to transport concrete along a pipeline to a designated location. Common concrete pumps on the market include trailer pumps, concrete mixer pumps, boom pumps, etc.

11.Concrete floats

Concrete floats are mainly used for plastering the building surfaces, or for smoothing and caulking plastered surfaces. There are different types and sizes of concrete floats to suit the needs of different occasions.

12.Concrete knee boards

When you’re working on wet concrete, the concrete kneeling board supports your weight and avoids damage to the smooth concrete plane. And it can help you move on the concrete, so that you can complete the work of leveling the concrete faster.

13.Trowels

A trowel is a small iron tool with a handle that can be used to chop brick, plaster, and build walls and is shaped like a knife. During construction, the worker first uses the trowel to shovel up the plaster and then spreads it on the construction site.

14.Shovels

Shovel is a common tool for digging and moving materials, widely used in agriculture, construction, gardening and other fields. Commonly used shovels are square-headed shovels and pointed-headed shovels.

In concrete construction, it can be used to manually mix concrete mixetures and also to fill the gaps left in the concrete pouring stage.

15.Screeds

After the concrete has been poured, you can use a screed to scrape off the excess concrete to make the surface smooth and level. The screed can be made of wood or a special aluminum tool. And, it is available in many different sizes and dimensions.

16.Thermo-hygrometer

A thermo-hygrometer is a tool used to measure ambient temperature and humidity. According to the results of the measurement, the construction conditions or the production and storage conditions of the products are determined.

17.Rake

The concrete rake can spread fresh concrete evenly, greatly improving the efficiency of work. The rake head with hooks can easily hook out the debris that are not easy to continue to use such as steel bars in construction, reducing the difficulty of construction and speeding up the construction process.

18.Concrete vibrators

Concrete vibration means that when the components are poured with the well-mixed concrete, the air bubbles must be discharged and tamped to eliminate the honeycomb pitting of the concrete, improve the strength of the concrete, and ensure the quality of the concrete components.

19.Wheel barrow

The wheel barrow is a traditional and lightweight transport tool that one person can push. It is mainly used to move small amount of materials, such as cement, stone, sand, concrete, etc., on the construction site.

Tools for finishing concrete

20.Concrete moisture meter

The concrete moisture meter is mainly used in industries that need to quickly determine the moisture content, such as the rapid determination of moisture on concrete, walls, floors, etc. It determines the moisture content of concrete floor without drilling holes on the measured object, just put the instrument probe against the surface of the measured object to measure its moisture content. The process is fast and saves time.

21.Groove cutter and edgers

Groove cutters, also known as grooving machines. Some concrete projects require grooves in the top of the concrete slab for better construction, and a grooving machine is the tool used to do this job.

A similar tool is an edger, which is used to create a slightly rounded decorative surface for the edges of the concrete.

22.Hammer drills or power drills

The hammer drill or power drill is used to complete work such as drilling by rotation and impact action. It plays an important role both in the construction and decoration phases of a project. Moreover, it can be used to test the relative humidity of the concrete when drying it.

23.Hand sprayer

Use a hand sprayer to spray curing compound on the surface of the concrete to reduce cracks and allow the concrete to set at the right rate. A hand sprayer allows you to do this more evenly and flexibly.

24.Polisher

After the concrete has set, if necessary, you can use a polisher to polish the concrete surface to achieve a smooth and flat effect. There are many types of polishing machines, so choose one according to your needs.

25.Relative Humidity (RH) test kit

While the thermo-hygrometer is mainly used to measure the humidity on the surface of the space, the relative humidity test kit is mainly used to measure the humidity inside the concrete slab. It can provide concrete contractors with the moisture data they need to help them perform better. In addition, it can also measure moisture for a wide range of wood flooring materials.

26.Saw

There are many different types of saws and their use in concrete work is common. If you are going to use a saw to cut concrete then you need to ensure the quality of the saw guard and the sharpness of the saw blade used. It can also be used for demolition and removal of scrap concrete.

27.Tape measure

A tape measure is a measuring tool. And concrete work is a job that requires accuracy and precision, so that’s when a tape measure is especially important. Moreover, the tape measure is compact and easy to carry.

Professional tools are essential if you want to be a professional concrete contractor. They can not only greatly improve your work efficiency, but also enhance the professionalism of your work. If you have any questions, please feel free to consult us!