Home » Concrete Mixers » Twin Shaft Concrete Mixer

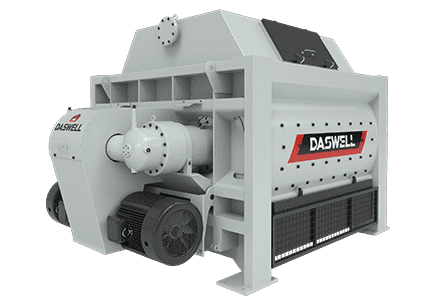

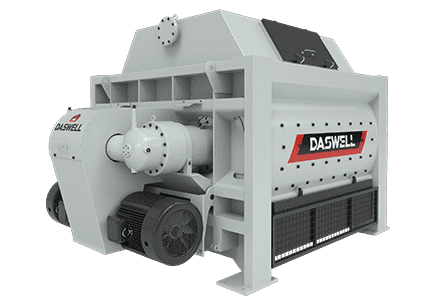

Twin Shaft Concrete Mixer

The twin-shaft mixer is a new type of mixing host developed by our company on the basis of absorbing advanced technology. It has excellent mixing effect for dry-hardness, semi-dry-hardness, plasticity and various proportions of concrete.

Charging Volume:

800-6000L

Discharging Volume:

500-4000L

What is twin shaft concrete mixer?

The twin-shaft mixer is a forced mixer, so named because it has two horizontal mixing shafts inside. It can mix dry hard concrete, plastic concrete, fluid concrete, light aggregate concrete and various mortars. Suitable for all kinds of construction projects, concrete batching plants and precast construction plants. It has the advantages of high degree of automation, good mixing quality, low noise, convenient operation, fast unloading speed, convenient maintenance and so on. In short, twin shaft horizontal mixer is a very ideal mixer at present.

Working principle of twin shaft mixer

- The mixing system of the twin-shaft concrete mixer is mainly composed of two mixing shafts and mixing blades that rotate in opposite directions.

- Several groups of stirring blades are respectively installed on the two main shafts, with a certain space staggered around them. Thereby, the mixture is stirred alternately between the two stirring shafts.

- On the one hand, turn the material at the bottom and middle of the mixing drum upwards. On the other hand, the mixture is pushed forward and backward along the axis. Through these steps, the mixture is stirred quickly and uniformly.

Twin shaft mixers highlights

1. Various product specifications. There are 0.5m³, 0.75m³, 1m³, 1.25m³, 1.5m³, 2m³, 3m³ and other capacities for your choice. The specific details of each model can be found in the parameter table below our article.

2. Good sealing, avoid slurry leakage. Our mixers use 6-layer shaft end sealing technology for excellent sealing. At the same time, it can also prevent damage to the machine due to slurry leakage.

3. Multiple sets of stirring blades in the mixing drum are staggered, which can quickly and fully mix the materials in the drum.

4. Wear parts are made of wear-resistant cast alloy steel, which can prolong the service life of the stirring device.

5. Equipped with automatic lubrication system, four pump cores supply oil to four shaft heads respectively. It can reduce the customer’s repair and maintenance work on the machine.

Twin shaft concrete mixer manufacturer

Manufacturer: Daswell Machinery

Two types of mixers: Small mixer – equipped with skip hopper – capacity: 500-1500L – for small concrete batching plants

Large mixer – equipped with belt conveyor – capacity: 1500-4000L – for medium and large concrete batching plants

Exporting Countries: Philippines, Iran, Egypt, Thailand, Vietnam, UAE, Russia, Kuwait, Mexico, Colombia, Malaysia, India, etc.

Branches and offices: Philippines, Egypt, Indonesia, Pakistan, Bangladesh

Customer evaluation: The design is more in line with practice, the raw materials are better, and the processing technology is more exquisite.

Customized solution service: If customers need customization, we will also cooperate with customers to develop equipment suitable for specific needs.

Twin shaft mixer maintenance

Buying a high-quality mixer is an important step, and later maintenance is also a step that cannot be ignored. If properly maintained, it can greatly extend the life of the machine. Here are some useful tips for you.

Routine inspection before work:

Before starting the machine, be sure to check whether the mixing host is normal and whether there is any residual mixing material in the machine compartment. If there is, it must be cleaned up before starting. Effectively prevent the solidified mixture from causing damage to the equipment.

Check the gap between the stirring blade and the liner:

The size of the gap between the stirring blade and the lining plate is related to the operation of the stirring host equipment. Once the gap is too large, the stones may be stuck between the stirring blade and the lining plate, resulting in the inability of the stirring host to operate. Seriously even directly damage the stirring shaft and motor of the host. Therefore, once the gap between the stirring blade and the lining plate is greater than 8MM, it is recommended that the relevant staff debug or replace the stirring blade.

Replacing the lubricating oil of the mixer gear box:

Under normal circumstances, after the new equipment runs for 50 hours, it is recommended to replace the lubricating oil of the gearbox. After every 1000 hours of work, the operator needs to change the lubricating oil. The purpose is to ensure that the lubricating oil reaches the shaft head of the agitator shaft.

Technical Data:

| Model | TCM500 | TCM750 | TCM1000 | TCM1250 | TCM1500 | TCM2000 | TCM3000 | TCM3500 | TCM4000 |

| Charging Volume (L) | 800 | 1200 | 1500 | 1750 | 2250 | 3000 | 4500 | 5300 | 6000 |

| Discharging Volume (L) | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 3000 | 3500 | 4000 |

| Max. Aggregate Size (mm) | 40/50 | 40/60 | 80/100 | 80/100 | 80/100 | 80/100 | 80/120 | 80/120 | 80/150 |

| Weight (t) | 4 | 5.5 | 5.2 | 5.5 | 5.8 | 7.5 | 9.2 | 9.6 | 12.2 |

| Mixing Power (kw) | 18.5 | 30 | 18.5 | 22×2 | 30×2 | 37×2 | 55×2 | 55×2 | 75×2 |

| Dimension (mm) | 3050 × 2530 × 2680 | 3110 × 2620 × 2580 | 2810 × 3200 × 1920 | 3020 × 2000 × 1920 | 3230 × 2000 × 1920 | 3460 × 2320 × 2140 | 3880 × 2600 × 2200 | 4100 × 2600 × 2200 | 4670 × 2600 × 2200 |

| Mixing Time (s) | ≤72 | ≤72 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |