Home » Concrete Mixers » Planetary Concrete Mixer

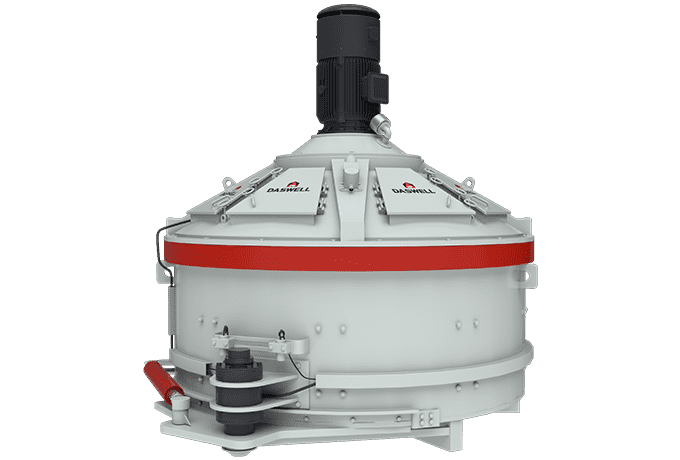

Planetary Concrete Mixer

Planetary mixers are ideal for mixing high performance and dry hard materials. Therefore, it is widely used in building materials, refractory materials, chemical industry, casting, metallurgy, ceramics, glass and other industries.

What is a planetary concrete mixer?

Planetary concrete mixer, also known as vertical shaft concrete mixer. Among them, the word planet in the name is mainly because of its unique stirring principle. Specifically, the stirring device of the planetary mixer also revolves while rotating. This is very similar to the motion of planets in the universe, hence the name. And this stirring principle makes its stirring efficiency and stirring effect very good. Therefore, it is widely used in building materials, refractory materials, chemical industry, foundry, metallurgy, ceramics, glass and other industries.

Why choose a planetary concrete mixer?

Concrete mixers can be divided into forced mixers and self-falling mixers according to their working principles. Among them, planetary mixers and twin-shaft mixers are mandatory concrete mixers.

First of all, compared with the twin-shaft mixer, the mixing arm of the vertical shaft mixer has a denser running track, and there is almost no mixing dead angle. Therefore, it stirs the material more fully. Often used to mix high performance and dry hard materials.

Then, the self-falling mixer uses the rotation of the mixing drum to make the concrete mixture do free-fall overturning stirring in the mixing drum, so as to achieve the purpose of mixing. The mandatory mixer drives the stirring blades to stir the materials in the tank through the stirring arm. Compared with the two, the forced mixer has a stronger mixing action, shorter mixing time, and can prepare special concrete.

To sum up, the forced mixer is better. Among them, the planetary mixer undoubtedly stands out.

Components of planetary mixer

The components of the planetary mixer can be roughly divided into mixing system, discharge system, drive system, access door and safety device, and waterway device.

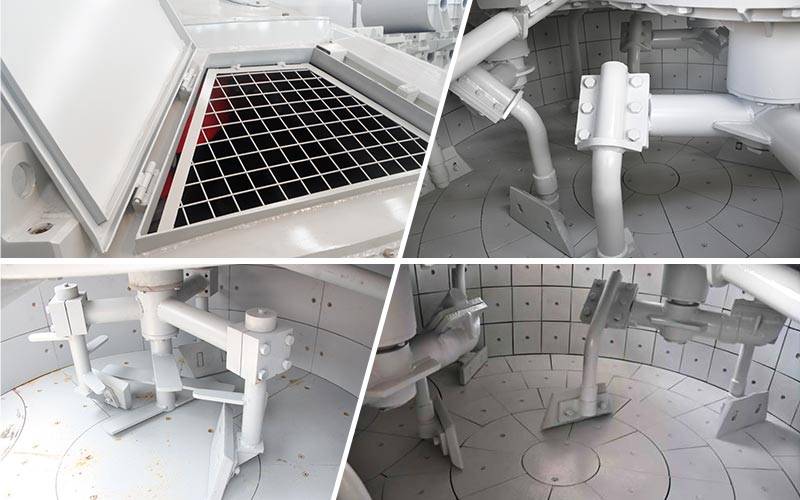

1. Stirring system: It is the core system of the whole mixer, including stirring shaft, stirring arm and stirring blade.

2. Unloading system: The unloading door can be opened by hydraulic and pneumatic methods to meet the requirements of different customers. There are up to three discharge doors. A special sealing device is set on the discharge door to ensure that the sealing is firm and there is no possibility of material leakage.

3. Inspection door and safety device: In order to facilitate inspection and cleaning, the Daswell planetary concrete mixer machine is equipped with a large-sized inspection door; the inspection door is equipped with a safety switch, which has high sensitivity.

4. Waterway device: It adopts the top-mounted form to solve the remaining problems of residual additives and water in the pipeline. A specially designed sprayer is installed on the spray pipe, which makes the spraying area larger and the mixing more uniform.

5. Drive system: motor + reducer

Why Daswell planetary mortar mixer?

1. Our mixer adopts a unique modular design, which has the advantage of easy disassembly and assembly. Suitable for various batching plants, concrete prefabricated parts factories.

2. Our company has designed a unique mixing system: the use of streamlined mixing arms can effectively prevent the shaft from sticking to the mixer. The stirring blade is a parallelogram, which can be turned 180° for repeated use. Thereby at least double the utilization rate.

3. Wear-resistant materials are used for the wearing parts of the mixer, such as shaft end seals, lining plates, mixing arms, and mixing blades. Thereby reducing machine downtime and improving work efficiency.

4. The whole machine adopts a fully sealed device, which can effectively avoid slurry leakage and reduce environmental pollution.

5. Up to three discharge doors can be opened at the same time, saving working time.

6. It adopts self-developed reducer. Not only the speed configuration is reasonable, but also basically no noise during operation. And high reliability, easy maintenance.

7. High-quality after-sales service: We will set up a WhatsApp group for each customer so that we can provide corresponding solutions in a timely manner. No matter what time and place you ask what kind of technical questions, skilled engineers will give you feedback at the first time, so that you have no worries.

How to choose?

First, the capacity of the planetary mixer needs to be confirmed. With different capacities, the amount of concrete mixed in each batch is different, resulting in a different overall production cycle.

Next, look at the configuration of the machine. Specifically, it refers to the discharge method and the number of discharge doors.

The unloading method can be pneumatic unloading or hydraulic unloading. Generally 0.75 square and below, the standard configuration is pneumatic discharge. 1 square and above, it is hydraulic unloading. Generally speaking, the discharge door will be equipped with one.

If the customer needs two or more discharge doors, we can make appropriate configuration according to the customer’s special requirements.

Besides that, if you need to use it with the production line, you can choose a stand-alone machine. If you need to use it alone, you can also choose to equip a batching hopper lifting system and platform.

If you still don’t know how to choose, you can tell us the project information. After that, professional technicians will recommend the appropriate model for you, so that you can buy the most efficient mixer at the lowest price.

Frequently-asked questions of planetary concrete mixer

Q: The voltage in our country is 440V, 60HZ, 3-phase. Can your machine be used?

A: We can equip the equipment with a motor of the appropriate voltage according to your local voltage.

Q: How long will it take for delivery?

A: The delivery date needs to refer to China’s voltage 380V, 50HZ, 3 phases. If the same, the delivery time is about 10-15 days. If it is a special voltage, the motor needs to be customized, and the delivery time is about one month.

Q: Have your vertical shaft mixers been exported?

A: Our vertical shaft mixers are exported to many countries. For example: Ireland, Mexico, Colombia, Egypt, Tunisia, Thailand, etc.

Q: What if I need to replace the accessories?

A: We have set up a special spare parts library, and the commonly used wearing parts are in stock all the year round. Prevent customers from affecting production due to untimely supply of accessories. And we will choose the fastest shipping method, so you don’t have to worry about such problems.

Q: Do you have a warranty period?

A: Our product warranty period is usually one year. During the warranty period (within 12 months from the date of completion of commissioning), repair services are provided for damage caused by human causes. During this period only the materials and accessories used for the repair will be charged. Our company is responsible for repairing or replacing any problems or damages that are not caused by human causes.

Technical Data:

| Model | PCM330 | PCM500 | PCM750 | PCM1000 | PCM1500 | PCM2000 | PCM2500 | PCM3000 |

| Discharging Volume (L) | 330 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 3000 |

| Charging Volume (L) | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 |

| Input Mass (kg) | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 |

| Mixing Power (kw) | 15 | 18.5 | 30 | 37 | 55 | 75 | 90 | 110 |

| Discharge Power (kw) | 2.2 | 2.2 | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Lifting Power (kw) | 4 | 4 | 7.5 | 11 | 15 | 22 | — | — |

| Skipper Capacity (L) | 580 | 870 | 1300 | 1740 | 2610 | 3480 | — | — |

| Skipper Mass (kg) | 870 | 1305 | 1950 | 2610 | 3615 | 5220 | — | — |

| Skipper Speed (m/s) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | — | — |

| Weight (kg) | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 |

| Dimension (mm) | 1910 x 1590 x 1747 | 2220 x 2071 x 1880 | 2581 x 2336 x 2195 | 2891 x 2602 x 2217 | 3223 x 2902 x 2425 | 3625 x 3230x 2630 | 2893 x 3550 x 2695 | 3893 x 3550x 2975 |