Sand and Gravel Aggregate FAQs

Sand and gravel aggregate is a collective name for materials such as sand, gravel, crushed stone, block stone, and dressed stone. It is a basic material for the production of concrete, mortar, asphalt mixture, etc., and is mainly used for infrastructure construction such as high-rise buildings, highways, railways, bridges, municipal engineering, water conservancy projects, airports, and wharfs.

Aggregate with a particle size larger than 5mm is called coarse aggregate, which is what we often call stone. Aggregate with a particle size of less than 5mm is called fine aggregate, also known as sand.

This article summarizes 15 frequently asked questions about sand and gravel aggregates. I hope we can bring some help in the construction.

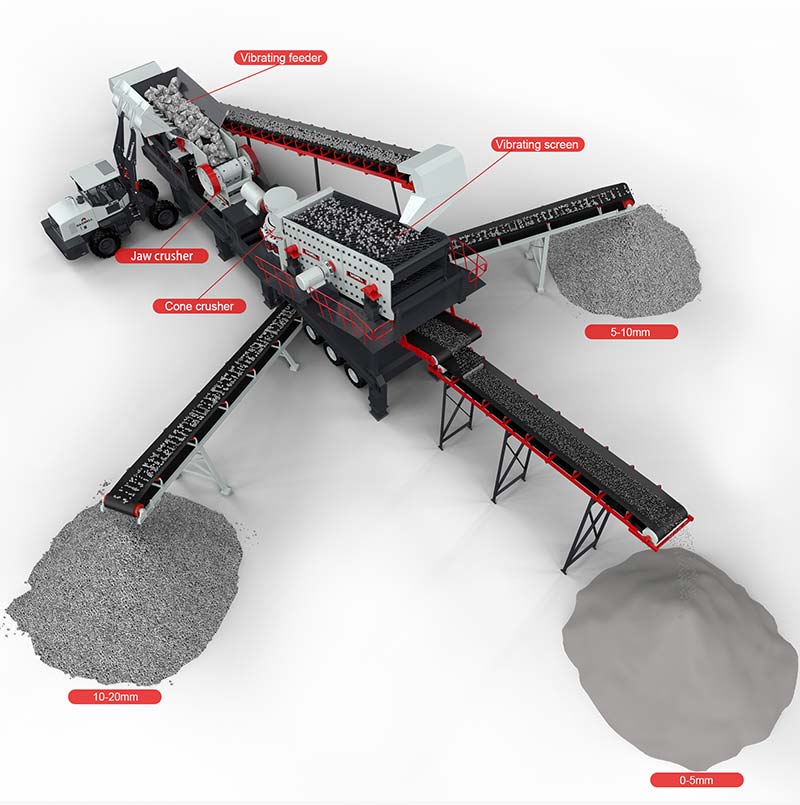

Q: What systems are generally composed of sand and gravel aggregate production lines?

A: It mainly includes four systems:

Feeding system: Generally, a vibrating feeder is used to be responsible for the supply of stone;

Transportation system: The belt conveyor is responsible for the transportation of materials between different equipment;

Crushing system: This is the core of the entire production line, which generally consists of multiple crushers. Its function is to crush various ore raw materials to the required particle size;

Screening system: It includes circular vibrating screen and linear vibrating screen.

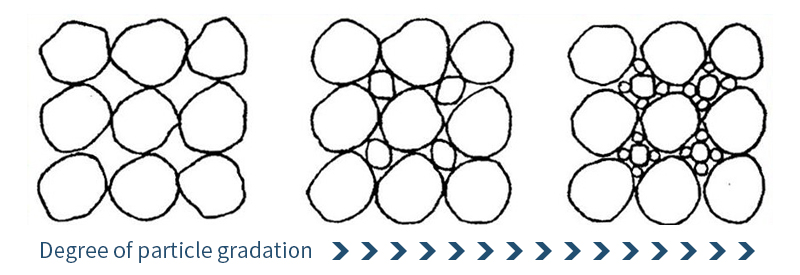

Q: What is aggregate gradation?

A: Aggregate gradation is the proportional relationship between the particles of different particle sizes that make up the sand and gravel aggregate. That is to say, the aggregate contains the proportion of particles with different thicknesses, which is an indicator to measure the thickness of the aggregate.

Different sands have different gradations. The smaller the particle size and the larger the proportion, the finer the sand. Conversely, the larger the proportion of particles with larger particle sizes, the coarser the sand. The same is true for stones.

Q: What are the mud content, stone powder content and clay lump content?

A: Mud content refers to the content of particles with a particle size of less than 75μm in natural sand;

The stone powder content refers to the content of particles with a particle size of less than 75μm in artificial sand;

The content of clay lumps refers to the content of particles in the sand whose original particle size is greater than 1.18mm and less than 600μm after being immersed in water and kneaded by hand.

Q: What is the particle gradation and fineness of sand? What effect do they have?

A: Particle gradation: This refers to the situation where sands of different particle sizes are matched with each other. If the particle gradation is poor and the void rate is large, more cement paste is needed to fill. On the contrary, if the particle gradation is good and the void rate is small, less cement paste filling is required.

The thickness of the sand: This refers to the average thickness of sand of different particle sizes when mixed together. Under the conditions of the same amount of sand, the surface area of coarse particles is small, and the surface area of fine particles is large, and the amount of cement paste used to wrap the particles will be different.

It was found that when mixing concrete, the thickness and particle gradation of sand should be considered at the same time. When the sand contains more coarse particles, moderately medium particles and a small amount of fine particles, there is both a smaller void rate and a smaller total surface area. In addition, this not only reduces the amount of cement, but also improves the compactness and strength of the concrete.

Q: What matters should be paid attention to when coarse and fine aggregates enter the production site?

A: Coarse aggregate should mainly control its particle size, gradation, particle shape, stone powder content, and clay lump content.

Fine aggregate should control fineness modulus, mud content and clay lump content.

In addition, no matter coarse aggregate or fine aggregate, macro inspection should be carried out for each vehicle, and unqualified vehicles shall not be unloaded. In addition, according to the requirements of the specification, the indicators should be inspected in batches.

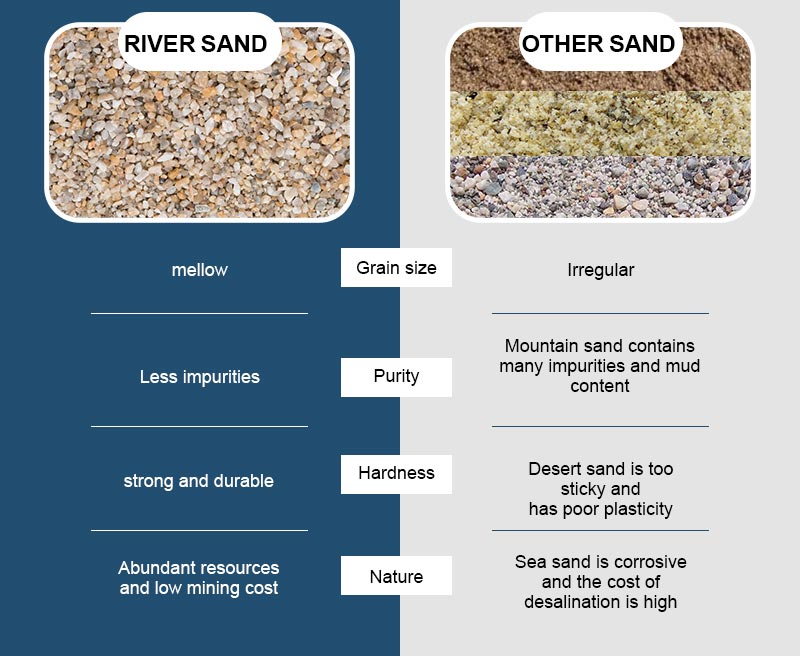

Q: What are the characteristics of river sand? Why are mountain sand, sea sand and desert sand not suitable for construction sand?

A: River sand has the advantages of good grain shape, firmness, durability, abundant resources, low mining cost and less impurities.

Mountain sand is easily weathered, with rough surface, many edges and corners, many impurities and large mud content.

Although sea sand is rich in resources, it has many impurities and chloride ions, which is corrosive and has high desalination costs.

Desert sand is too fine, contains a lot of soil, is too sticky, and has poor plasticity.

Therefore, mountain sand, sea sand and desert sand cannot be used as construction sand.

Q: How to distinguish artificial sand and river sand from the appearance?

A: Artificial sand is the sand and gravel aggregate obtained after being crushed by sand making machine such as vertical shaft impact crusher. Compared with natural river sand, it has the characteristics of sharp edges and corners, many needles and roughness.

River sand is dug directly from the river, so it will be mixed with small pebbles and fine sand.

The river sand is eroded by the river water for a long time, and the edges and corners are relatively rounded. The edges and corners of the artificial sand produced by the sand and gravel equipment are relatively sharp and distinct.

Q: What types of sand can be classified according to technical requirements?

A: Sand is divided into Class I, Class II and Class III according to technical requirements:

Class I is suitable for concrete with strength grade greater than C60;

Class II is suitable for concrete with strength grades between C30 and C60 and with frost resistance, impermeability or other requirements;

Class III is suitable for concrete and building mortar with strength grade less than C30.

Q: What is the role of sand and gravel aggregate in concrete production?

A: Sand and gravel aggregate can provide good stability, wear resistance and durability to concrete. Moreover, it can also play the role of reducing shrinkage, inhibiting crack propagation, and reducing heat of hydration. Adding as much aggregate as possible to concrete can reduce the cost of concrete without affecting its properties.

Q: If the sand is too fine, what is the effect on the concrete? What if only fine sand is available?

A: If the sand is too fine, the water demand of the concrete goes up. In addition, the concrete prepared with fine sand has poor pumpability and plasticity, and the strength of the concrete will decrease, and it is easy to crack.

If there is only fine sand in the sand source, the pumped concrete can be prepared by adding some machine-made sand with the fine sand. For example, fine sand with a fineness modulus of less than 2.0 can be mixed with machine-made sand with a fineness modulus of 3.0 to 3.2. The ratio between the two is about 6 to 4, and then observe the fluidity and pumpability. The specific ratio can be determined by experiment.

Q: If the sand contains a lot of mud, or even has clay lumps, will it have a big impact on the concrete?

A: This has an impact on the concrete. If the sand contains a large amount of mud, the water demand of the concrete will be large, the plasticity will be poor, the shrinkage will increase, the strength of the concrete will decrease, and the structure will be easy to crack. Therefore, it is necessary to control the mud content of sand to be less than or equal to 3% (C30~C50), and the mud content of high-strength concrete should be less.

As for the clay lumps, in addition to the above effects, it will also seriously affect the concrete strength. For example, clay lumps can weaken concrete sections, float up when the ground is poured, and form pits on the surface after shrinking.

Q: What is the appropriate amount of stone powder in concrete?

A: Adding stone powder to concrete is beneficial. However, the stone powder content should be appropriate.

The main component of stone powder in machine-made sand is calcium carbonate, but the hydration is not unlimited, and it is also limited by the composition of cement.

If the content of stone powder is too high, it is not conducive to the bonding of sand aggregate and cement, which will reduce the performance of concrete. In addition, when the stone powder content exceeds the limit, it is not conducive to the durability of concrete. This is because the water retention capacity of stone powder is obviously reduced, and the drying shrinkage is significantly larger.

Experiments show that generally, the content of stone powder in concrete below C50 should be controlled at 10% to 15%, while the content of stone powder in concrete above C50 should not exceed 10%.

Q: Why is the strength of pebble concrete 3~4MPa lower than that of crushed stone concrete for the same proportion of concrete?

A: The rough surface of the coarse aggregate is beneficial to enhance the interface strength between the cement paste and the aggregate.

According to the test, on the one hand, the concrete prepared with pebble contains more weathered stone, and its crushing index is lower than that of crushed stone. Moreover, its surface is smooth and the interface strength is low, so the strength of the concrete prepared by it will be 3~4MPa lower than that of the crushed stone concrete with the same proportion.

Q: What is the alkali-aggregate reaction? What’s the impact?

A: The alkali (Na2O, Ka2O) in the concrete reacts chemically with the aggregate whose chemical composition is active silica to form an alkali-silica gel and then absorb water and expand, and the expansion stress causes the concrete to crack. This process is called the alkali-aggregate reaction. This reaction will lead to local volume expansion inside the concrete, and even cause the concrete structure to have expansive failure.

Q: How to prevent alkali-aggregate reaction?

A: If the local coarse aggregate contains active silica, the alkali content of the concrete admixture should be strictly limited. When using alkaline aggregates, the total alkali content of various materials in the concrete should be less than or equal to 3% of the concrete mass.