Каменное раздавное растение

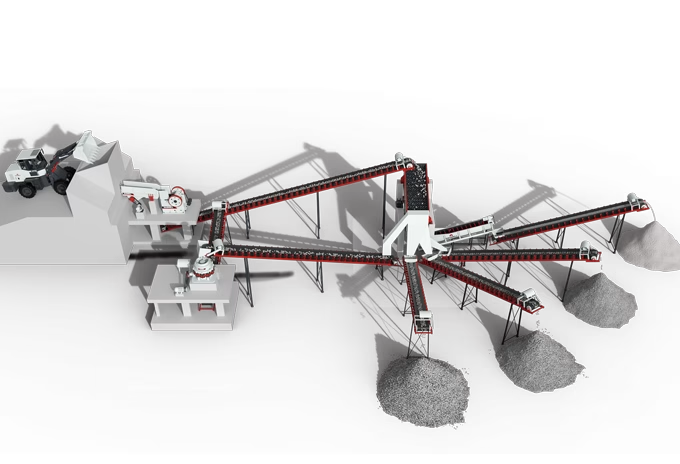

The stone crushing plant is a special equipment used to produce sand and gravel aggregates used in construction, шоссе, железные дороги, mining and other industries. Вообще говоря, a crushing plant is an entire production line composed of different equipment such as jaw crusher, Конус дробилка, Песчаная машина, вибрирующий экран, and belt conveyor.

Crushing capacity:

1-1000tph

Сырье:

речная камешка, известняк, Строительные отходы, гранит, и т. д.

The stone crushing plant is a special equipment used to produce sand and gravel aggregates used in construction, шоссе, железные дороги, водоснабжение, mining and other industries. Вообще говоря, a crushing plant is an entire production line composed of different equipment such as jaw crusher, Конус дробилка, Песчаная машина, sand washing machine, вибрирующий экран, and belt conveyor. According to the specific needs of different customers, we can customize personalized production line configurations.

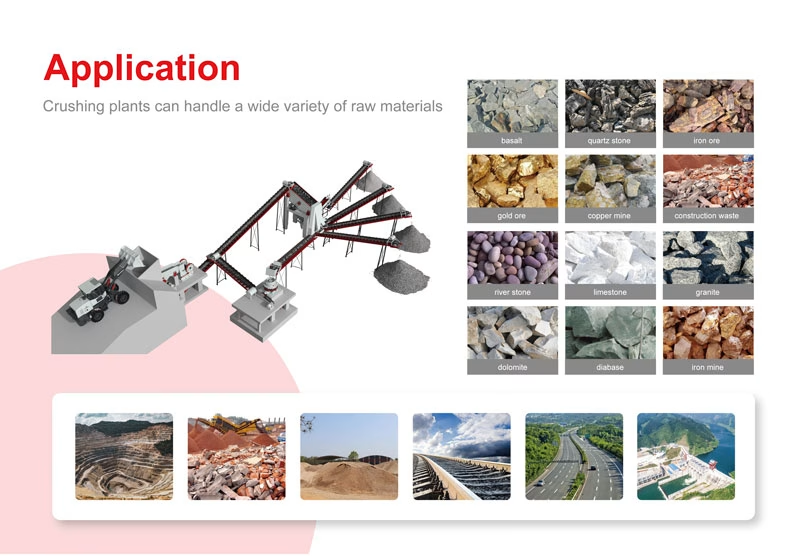

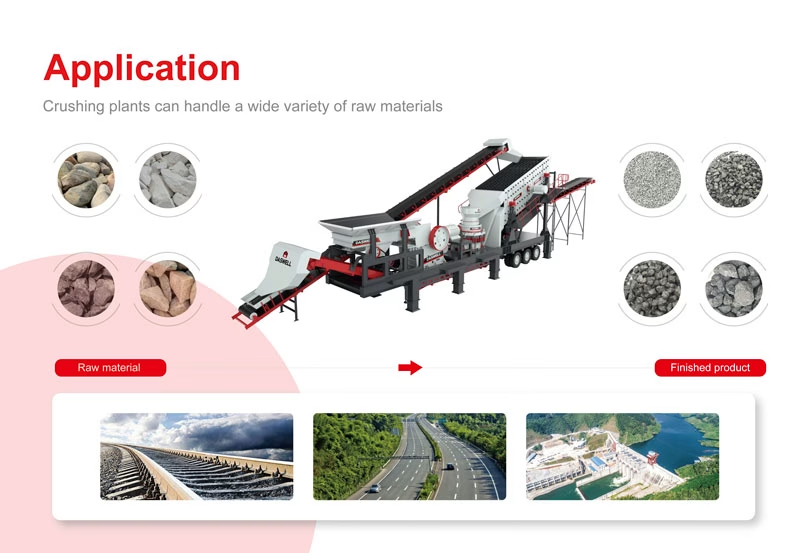

Applications of stone crusher plant

The stone crushing plant can process a wide variety of raw materials, including river pebbles, известняк, Строительные отходы, гранит, iron ore, базальт, гипс, и т. д.. The difference in raw materials will directly affect the selection of crusher model and the output of the production line.

Crushing plant are widely used in infrastructure construction, добыча, garbage treatment, stone processing, железные дороги, шоссе, water conservancy projects and other fields to provide them with high-quality sand and gravel aggregates.

From mining, строительство, garbage disposal to metallurgy, stone processing, и т. д., they are all inseparable from the key process of crushing. It can not only help reuse resources, reduce costs, and improve production efficiency, but also has a positive effect on environmental protection.

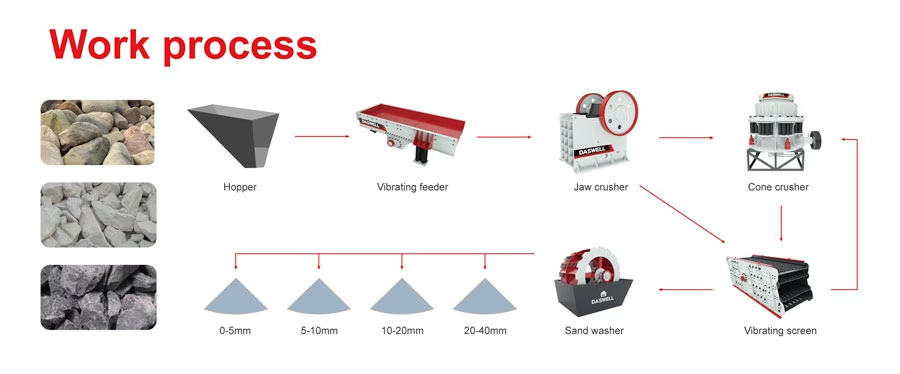

Workflow of stone crushing and screening plant

The process flow of the stone crushing and screening plant includes feeding, сокрушительный, screening, transportation and other links. If the requirements for the particle size of the finished product are high, sand making and other steps will be added after screening.

The following takes the configuration of a common crushing production line as an example to introduce its workflow. The production line includes vibrating feeder, ленточный конвейер, челюсть, Конус дробилка, вибрирующий экран, и т. д.:

Первый, raw materials need to be transported from the quarry to the construction site through transport equipment such as dump trucks. Then the raw materials are fed into the jaw crusher through a vibrating feeder. The materials undergo primary crushing in the jaw crusher.

The crushed materials enter the cone crusher through the belt conveyor for secondary crushing. The crushed materials are sent to the vibrating screen by a belt conveyor for screening. The screened materials, if they meet the particle size requirements of the finished product, can be directly sent to the stockpile through the belt conveyor. Materials that do not meet the particle size requirements of the finished product are transported again by the belt conveyor to the cone crusher for re-crushing until the materials meet the particle size requirements of the finished product.

It needs to be emphasized that different engineering projects and raw material types will lead to differences in the crushing plant process flow. Поэтому, in practical applications, engineers need to develop suitable process flows and configurations based on specific conditions.

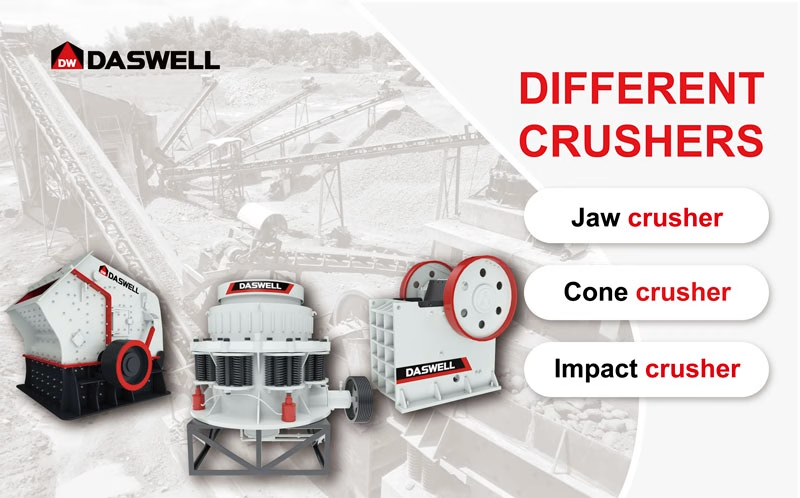

Choose different crusher machines for different crushing stages

In order to produce sand and gravel aggregates of suitable particle size for a complete crushing production line, Сырье обычно нужно пройти через три -четыре процесса раздавливания и формирования. At different crushing stages, different stone crushers are required. Используя различные характеристики оборудования, сырье можно раздавить до требуемого размера частиц.

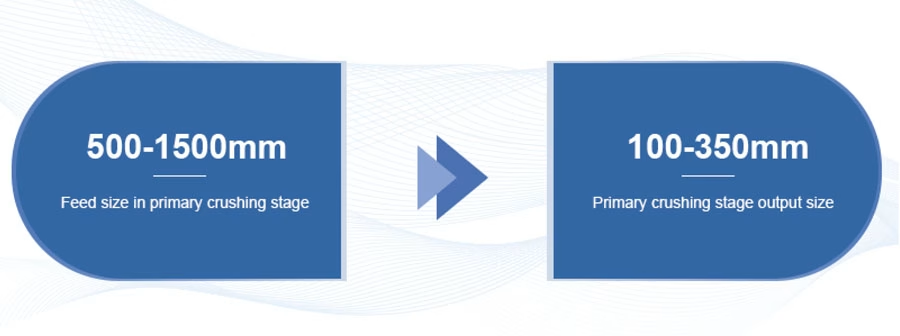

Primary crushing stage (coarse crushing)

Первичное сокрушение, также известен как грубое сокрушительное, is mainly used for the preliminary crushing of bulk materials. The particle size of the crushed materials is generally larger. На первичной стадии сокрушительного, the feed particle size is about 500 к 1500 мм, and the discharge particle size is generally 100 к 350 мм. Commonly used crushers in the primary crushing stage include jaw crushers and gyratory crushers.

Челюсть is an earlier type of crushing equipment. It has the advantages of simple structure, надежная операция, convenient maintenance and low cost. It mainly crushes materials through the mutual extrusion of jaw plates, и является первым выбором для сокрушительных твердых материалов, таких как гранит.

Gyratory crusher is also called vertical compound crusher. Due to its high crushing efficiency, large feed particle size, Простой производственный процесс и низкая стоимость технического обслуживания, the gyratory crusher has always been an ideal equipment for coarse crushing of hard materials in large mines and other fields.

Сеондри и Третичный Сокружение (medium and fine crushing)

Secondary and tertiary crushing, also known as medium crushing and fine crushing, mainly crush the materials after primary crushing. If a larger discharge particle size is required, secondary crushing can meet the requirements; if a smaller discharge particle size is required, tertiary crushing is required.

Во вторичной стадии сокрушительного, the material is crushed from 350~100mm to 100~40mm.

В третичной сокрушительном этапе, the material is broken from 100~40mm to 30~10mm.

Наиболее часто используемыми дробилками в среднем и тонком раздавливании являются дробилки и ударные дробилки. В последние годы, due to the emergence of fine jaw crushers, their lower costs have also been welcomed by some customers.

Конус дробилка is mainly suitable for crushing various rocks and ores with medium and above hardness such as granite and pebbles. Common types of cone crushers include spring cone crushers, Symons Cone Crusmers, сложные дробилки, hydraulic cone crushers, и т. д.. Клиенты могут выбрать соответствующую дробилку в конусе в соответствии с фактическими потребностями.

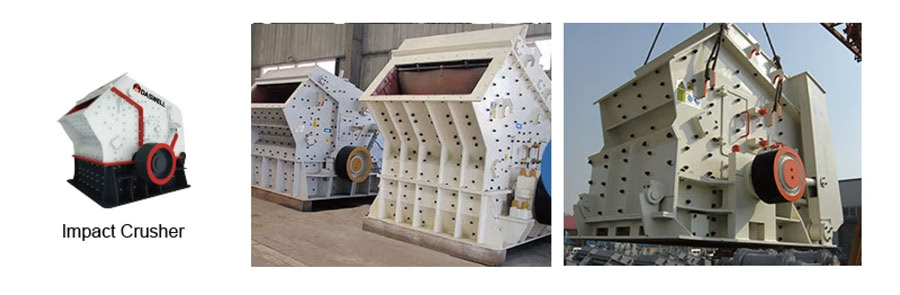

Ударная дробилка is a device that uses impact energy to crush materials. It is mainly used to crush brittle materials with medium hardness and below. The materials crushed by the impact crusher are mostly in the shape of cubes. В то же время, Он также имеет характеристики высокой эффективности производства, Большое соотношение дробления, good product particle shape, and strong impact resistance.

Стадия изготовления песка и формирования

If the size and shape of the produced materials cannot meet your requirements, you can consider adding a sand making machine to crush and shape the materials again. The commonly used equipment at this stage is a sand making machine.

Машина для изготовления песка также можно назвать дробилка с вертикальным валом. Он широко используется при изготовлении песка и формировании известняка, речная камешка, гранит, tailings and other materials. Он может обеспечить высококачественные пески и гравийные агрегаты для автомагистралей, municipal projects, бетонные перемешивающие растения, и т. д.. Вообще говоря, the feed particle size of the sand making machine is less than 40 мм, and the discharge particle size is 0 к 10 мм.

Sand washing stage

As the market’s requirements for the quality of finished sand increase, sand washing machines are becoming more and more popular among customers. The sand washing machine can wash away soil and other impurities in the finished sand to achieve purification.

Common sand washing machines include spiral sand washing machines and wheel bucket sand washing machines. Customers can choose different sand washing equipment according to their needs.

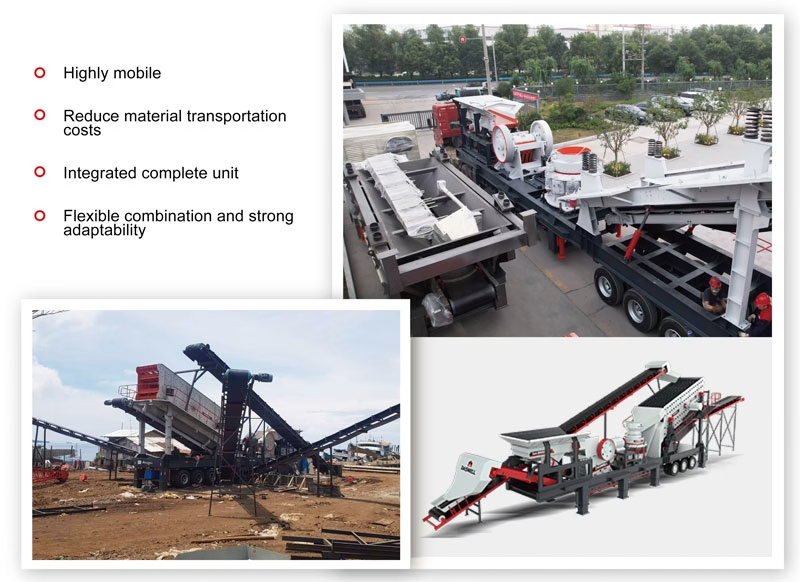

Mobile stone crushing plant

Mobile crushing plants are mainly used for material processing that often require relocation operations, especially for engineering operations with high mobility such as highways, железные дороги, and hydropower projects. Users can adopt a variety of configurations according to the type and scale of processed raw materials and finished product material requirements.

Типы мобильных заводов

Mobile crushing plants can be divided into crawler-type mobile crushing plants and tire-type mobile crushing plants.

Мобильный завод по мобильному красовому типу может быть перемещен сам по себе и управляется беспроводным пультом дистанционного управления. В основном используется в горных районах, водно -болотные угодья и суровая горная среда.

Завод мобильной дробилки шин полуосреда и необходимо отбуксировать полуприцеп при путешествии. В основном используется для утилизации строительных отходов, земляные работы, и строительство.

Features of mobile crusher plant

- Strong mobility: Different crushing equipment are installed on independent movable chassis. The wheelbase is short and the turning radius is small, so it can travel flexibly in the working area.

- Reduce material transportation costs: The mobile crushing station can process materials on site without having to move the materials away from the site for reprocessing, which greatly reduces material transportation costs.

- Integrated complete unit: The integrated unit eliminates the complicated site infrastructure work of separate components and reduces the consumption of materials and time. The compact space layout improves the flexibility of use.

- Flexible combination and strong adaptability: The tire mobile crushing plant can form a process of “crushing first and then screening” или “screening first and then crushing” according to different crushing process requirements. The mobile crusher plant can be combined into a two-stage crushing and screening system of coarse crushing and fine crushing according to actual needs, or it can also be combined into a three-stage crushing and screening system of coarse crushing, medium crushing and fine crushing, which has strong flexibility.

Часто задаваемые вопросы

Q.: How to get a quotation for a stone crushing plant?

А: Customers need to tell us: 1. What is the required output per hour? 2. What are the raw materials? 3. What is the feed size? 4. How many kinds of ingredients are produced? What are the output sizes?

We make plans and provide quotations for our customers based on their requirements.

Q.: Is your mobile crushing plant one vehicle or two vehicles?

А: Different designs can be made based on customer output requirements and local road conditions.

Q.: Can your crushing plant produce materials of different sizes?

А: Да, без проблем. В целом, materials are produced in 4 specifications, 0-5мм, 5-10мм, 10-20мм, and 20-30mm.

Q.: How to install a crushing and screening plant?

А: We can send 1-2 engineers to the customer site to guide the installation, and we can train local operators.