Дом » Бетонные смесители » Планетарный бетонный миксер

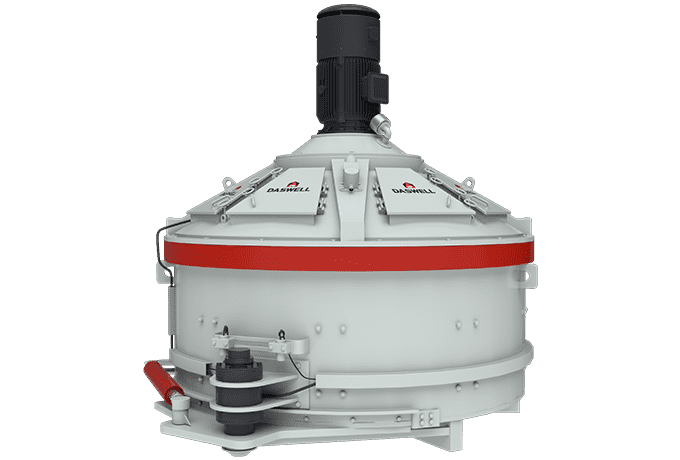

Планетарный бетонный миксер

Планетарные смесители идеально подходят для смешивания высокой производительности и сухих твердых материалов. Поэтому, это широко используется в строительных материалах, рефрактерные материалы, химическая промышленность, кастинг, металлургия, керамика, стекло и другие отрасли промышленности.

Разрядка объема(Л):

330-3000

Объем зарядки(Л):

500-4500

Что такое планетарный бетонный миксер?

Планетарный бетонный миксер, Также известен как бетонный миксер вертикального вала. Среди них, Слово планета во имя в основном из -за ее уникального принципа перемешивания. Конкретно, помешивающее устройство планетарного миксера также вращается во время вращения. Это очень похоже на движение планет во вселенной, Отсюда и название. И этот принцип перемешивания делает свою эффективность перемешивания и эффект перемешивания очень хорошим. Поэтому, это широко используется встроительные материалы, рефрактерные материалы, химическая промышленность, литейный завод, металлургия, керамика, стекло и другие отрасли промышленности.

Почему выбирают планетный бетонный миксер?

Бетонные миксеры можно разделить на принудительные миксеры и самодовольные смесители в соответствии с их принципами работы. Среди них, Планетарные смесители и смесители с двумя валами являются обязательными бетонными миксерами.

Прежде всего, по сравнению с миксером с двойным валом, Смешанная рука вертикального смесителя вала имеет более плотную бегущую дорожку, и почти не смешивает мертвый угол. Поэтому, он разжигает материал более полно. Часто используется для смешивания высокой производительности и сухих твердых материалов.

Затем, Самодовольственный миксер использует вращение смешанного барабана, чтобы заставить бетонную смесь сделать свободно переворачиваясь в перемешивающем барабане, чтобы достичь цели смешивания. Обязательный миксер управляет перемешивающимися лопастями, чтобы размешать материалы в резервуаре через мешающую руку. По сравнению с двумя, Принудительный миксер имеет более сильное смешанное действие, Более короткое время смешивания, и может приготовить специальный бетон.

Подводить итоги, Принудительный миксер лучше. Среди них, планетарный миксер, несомненно, выделяется.

Компоненты планетарного микшера

Компоненты планетарного миксера можно примерно разделить на систему смешивания, система разряда, Система привода, доступ к двери и безопасности, и устройство водного пути.

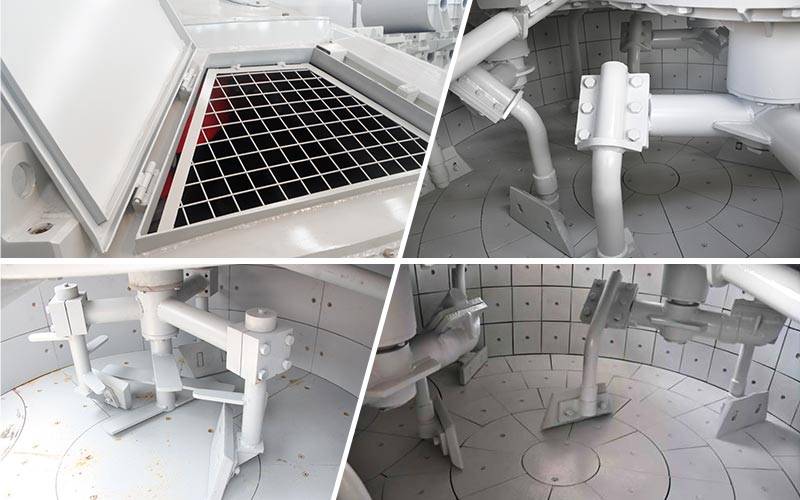

1. Система перемешивания: Это основная система всего микшера, в том числе перемешивающий вал, помешивающая рука и перемешивание лезвия.

2. Система разгрузки: Дверь разгрузки может быть открыта гидравлическими и пневматическими методами для удовлетворения требований различных клиентов. Есть до трех дверей выписки. Специальное герметизирующее устройство установлено на дверь сброса, чтобы убедиться, что уплотнение является твердым и нет возможности утечки материала.

3. Проверка и безопасное устройство: Для облегчения проверки и уборки, Машина Daswell Planetary Boncret Mixer оснащена дверью для проверки большого размера; Дверь проверки оснащена выключателем безопасности, который обладает высокой чувствительностью.

4. Устройство водного пути: Он принимает верхнюю форму для решения оставшихся проблем остаточных добавок и воды в трубопроводе. Специально разработанный распылитель установлен на трубе Spray, что делает площадь распыления больше и смешивание более равномерной.

5. Система привода: мотор + редуктор

Почему микшер Daswell Planetary?

1. Наш микшер принимает уникальный модульный дизайн, который имеет преимущество легкой разборки и сборки. Подходит для различных партийных растений, Бетонные сборные запасные запасные фабрики.

2. Наша компания разработала уникальную систему микширования: Использование потоковых смесительных рычагов может эффективно предотвратить прилипание вала к миксеру. Перемешающее лезвие - это параллелограмм, который можно повернуть на 180 ° для повторного использования. Тем самым, по крайней мере, удвоите частоту использования.

3. Износостойкие материалы используются для ношения частей миксера, такие как конец вала, подкладочные пластины, смешивание рук, и смешивание лезвий. Тем самым сокращая простоя машины и повышение эффективности работы.

4. Вся машина принимает полностью запечатанное устройство, который может эффективно избежать утечки суспензий и уменьшить загрязнение окружающей среды.

5. До трех дверей для выписки могут быть открыты одновременно, Экономия рабочего времени.

6. Он принимает саморазвитый редуктор. Не только конфигурация скорости является разумной, но также в основном нет шума во время работы. И высокая надежность, Легкое обслуживание.

7. Высококачественная послепродажная служба: Мы создадим группу WhatsApp для каждого клиента, чтобы своевременно предоставлять соответствующие решения. Независимо от того, в какое время и место вы задаете, какие технические вопросы, Квалифицированные инженеры впервые дадут вам отзыв, так что вы не заботитесь.

Как выбрать?

Первый, Пропускная способность планетарного миксера должна быть подтверждена. С различными способностями, Количество бетона, смешанного в каждой партии, отличается, приводя к другому общему производственному циклу.

Следующий, Посмотрите на конфигурацию машины. Конкретно, это относится к методу разряда и количеству дверей разряда.

Метод разгрузки может быть пневматической разгрузкой или гидравлической разгрузкой. В целом 0.75 квадрат и внизу, Стандартной конфигурацией является пневматический разряд. 1 квадрат и выше, это гидравлическая разгрузка. Вообще говоря, дверь сброса будет оснащена одним.

Если клиенту нужны две или более двери выписки, Мы можем сделать соответствующую конфигурацию в соответствии со специальными требованиями клиента.

Кроме того, Если вам нужно использовать его с производственной линией, Вы можете выбрать автономную машину. Если вам нужно использовать его в одиночку, Вы также можете оснастить систему и платформу для подъема бункеров.

Если вы все еще не знаете, как выбрать, Вы можете сообщить нам информацию о проекте. После этого, Профессиональные техники порекомендуют вам подходящую модель, чтобы вы могли купить самый эффективный миксер по самой низкой цене.

Часто задаваемые вопросы планетарного бетонного миксера

Q.: Напряжение в нашей стране 440 В, 60Гц, 3-фаза. Можно ли использовать вашу машину?

А: Мы можем оборудовать оборудование двигателем соответствующего напряжения в соответствии с вашим локальным напряжением.

Q.: Сколько времени потребуется для доставки?

А: Дата доставки должна относиться к напряжению Китая 380V, 50Гц, 3 фазы. Если то же самое, Время доставки о 10-15 дни. Если это специальное напряжение, Мотор должен быть настроен, И время доставки составляет около месяца.

Q.: Были ли экспортированы ваши вертикальные миксеры вала?

А: Наши смесители вертикального вала экспортируются во многие страны. Например: Ирландия, Мексика, Колумбия, Египет, Тунис, Таиланд, и т. д..

Q.: Что если мне нужно заменить аксессуары?

А: Мы создали специальную библиотеку запасных частей, и обычно используемые изношенные детали находятся в наличии в течение всего года. Предотвратить воздействие клиентов из -за безвременного поставки аксессуаров. И мы выберем самый быстрый метод доставки, Так что вам не нужно беспокоиться о таких проблемах.

Q.: У вас есть гарантийный период?

А: Наш гарантийный период обычно составляет один год. В течение гарантийного периода (в пределах 12 месяцы с даты завершения ввода в эксплуатацию), ремонтные услуги предоставляются на ущерб, вызванные людьми. В течение этого периода только материалы и аксессуары, используемые для ремонта. Наша компания отвечает за ремонт или замену любых проблем или ущерба, которые не вызваны человеческими причинами.

Технические данные:

| Модель | ПСМ330 | ПСМ500 | ПСМ750 | ПСМ1000 | ПСМ1500 | ПСМ2000 | ПСМ2500 | ПСМ3000 |

| Разрядка объема(Л) | 330 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 3000 |

| Объем зарядки(Л) | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 |

| Входная масса (кг) | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 |

| Смешивание мощности (кВт) | 15 | 18.5 | 30 | 37 | 55 | 75 | 90 | 110 |

| Мощность разряда (кВт) | 2.2 | 2.2 | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Подъемная сила (кВт) | 4 | 4 | 7.5 | 11 | 15 | 22 | — | — |

| Пропускная способность шкипера (Л) | 580 | 870 | 1300 | 1740 | 2610 | 3480 | — | — |

| Шкипер Месса (кг) | 870 | 1305 | 1950 | 2610 | 3615 | 5220 | — | — |

| Шкипер скорость (РС) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | — | — |

| Масса (кг) | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 |

| Измерение (мм) | 1910 x 1590 x 1747 | 2220 x 2071 x 1880 | 2581 x 2336 x 2195 | 2891 x 2602 x 2217 | 3223 x 2902 x 2425 | 3625 x 3230x 2630 | 2893 x 3550 x 2695 | 3893 x 3550x 2975 |