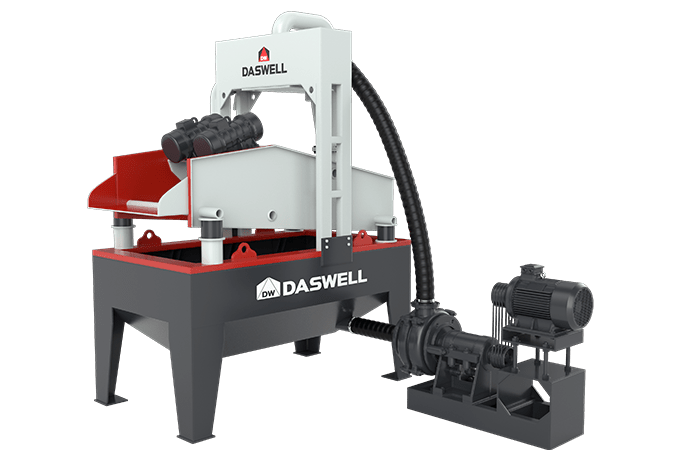

In the sand production line, the fine sand recycling machine is a relatively important sand recovery equipment. Its main function is to clean, dehydrate and classify sand. It can also be used in the dehydration link of the ceramic raw material processing system, the tailings recovery treatment in the concentrator, the processing system of quartz sand, the processing system of sand in hydropower stations, etc.

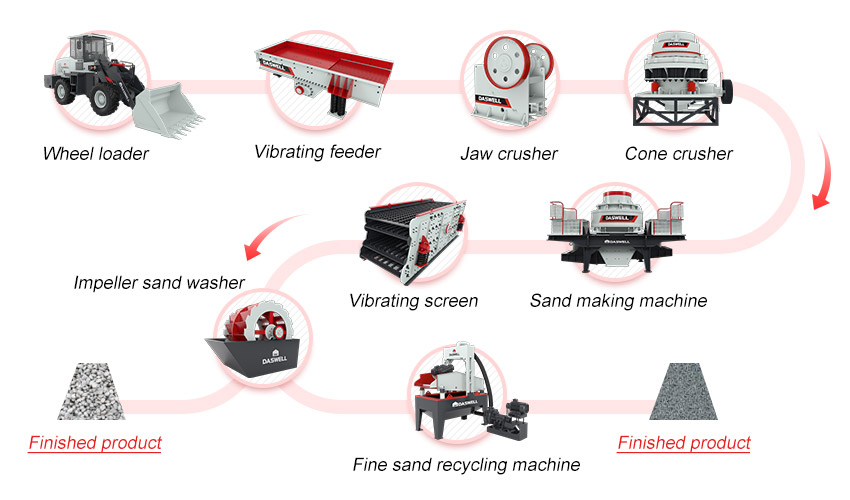

Application of fine sand recycling machine in machine-made sand production line

Most of the current artificial sand production line adopts wet production process. That is, the use of a sand washing machine to remove impurities from the machine-made sand. However, whether spiral sand washer or impeller sand washer is used, it will face the loss of fine sand. The consequences of this are as follows:

- The loss of fine sand below 0.35mm will affect the gradation of sand. As a result, the gradation and fineness modulus are unreasonable, which greatly reduces the product quality of machine-made sand;

- Too much fine sand and sludge entering the sedimentation tank will cause sedimentation in the sedimentation tank. It not only pollutes the environment, but also costs a lot to clean the sedimentation tank frequently;

- A lot of fine sand is lost, which greatly reduces the customer's income.

In response to the above problems, our company specially designed SRM series sand recycling machine. This machine is developed by our company on the basis of absorbing advanced technology, combined with the serious loss of fine sand in the actual production of customers. And it has been recognized by many sand and gravel manufacturers.

In actual use, the sand recycling equipment does not require additional water consumption. It can extract and recover more than 85% of the fine sand washed away from the originally discharged wastewater. The treated sand can be directly mixed into the finished product stack or stored separately as high-grade materials. Adding this machine to the machine-made sand production line can directly save more than 15% of the comprehensive economic benefits for customers.

How does the fine sand recycling machine work?

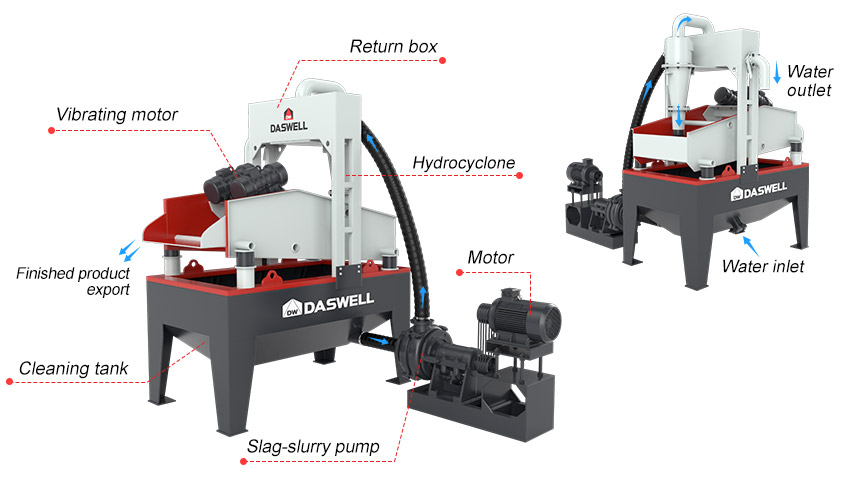

The fine sand recycling machine parts are mainly include vibration motor, hydrocyclone, dewatering screen, return box, cleaning tank, motor and slag-slurry pump.

- Connect the sand washing wastewater overflowing from the sand washing machine to the cleaning box of the fine sand recycling system.

- The sand-water mixture in the cleaning box is transported to the hydrocyclone at high speed under the action of the slag-slurry pump.

- The fine sand is centrifuged, classified and concentrated in the hydrocyclone, and finally discharged into the dewatering screen.

- Under the vibration of the dewatering screen, the fine sand and water are effectively separated.

- The treated fine sand is discharged through the discharge port, while a small amount of fine sand and mud are returned to the cleaning tank through the return box.

Features of sand recovery machine

- 95% of fine sand can be recovered, reducing the loss of fine sand. Improve economic efficiency while reducing environmental pollution.

- Fine sand is fully recovered, reducing the workload and cleaning cost of the sedimentation tank.

- The dewatering screen adopts polyurethane screen, which has a longer life than other types of screen and is not easy to block holes.

- The quality is firm and reliable, and the failure rate is extremely low.

- Our company can design corresponding solutions according to the different requirements of users.

- Referring to the national environmental protection standard, the noise is low. It can be equipped with dust removal equipment, and the construction environment fully meets the requirements of environmental protection.

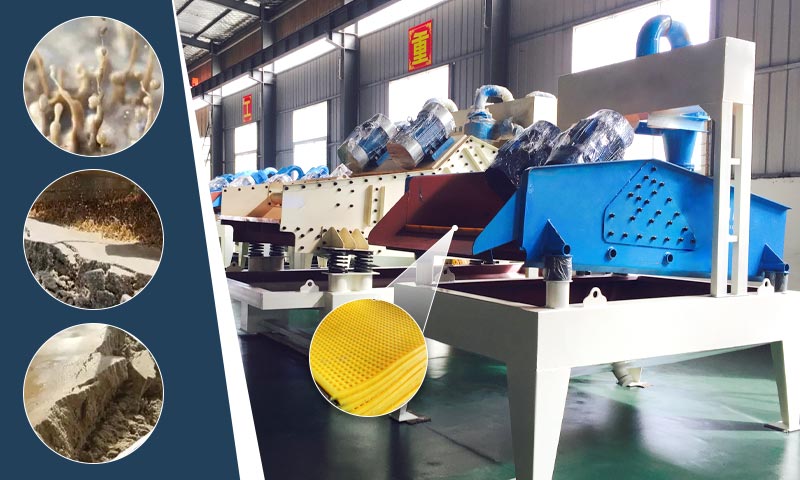

What are the advantages of using polyurethane mesh?

In fine sand collecting machine, dewatering screen is often worn by grit. It will affect the working efficiency and service life of the whole machine for a long time. Therefore, our company chooses the screen mesh made of polyurethane material. So, what are the advantages of polyurethane screens in fine sand recycling?

Stronger carrying capacity

Since the polyurethane screen uses steel wire rope as the skeleton material, it has strong bearing capacity and lifting force. Its load-bearing capacity is more than 2.5 times that of the rubber screen.

Better screening effect

Due to the strong water permeability of polyurethane and the large cone angle of the mesh, it can effectively avoid the adhesion of wet fine particles. It is very suitable for the screening and classification of wet and fine materials.

Higher screening accuracy

Polyurethane screen adopts the process of casting molding. Screens produced using this process have very precise apertures. This greatly improves the screening quality of the fine sand recycling equipment, ensuring that the fine sand particle size after screening can well meet the needs of users.

Factors affecting the treatment efficiency of the fine sand recycling machine

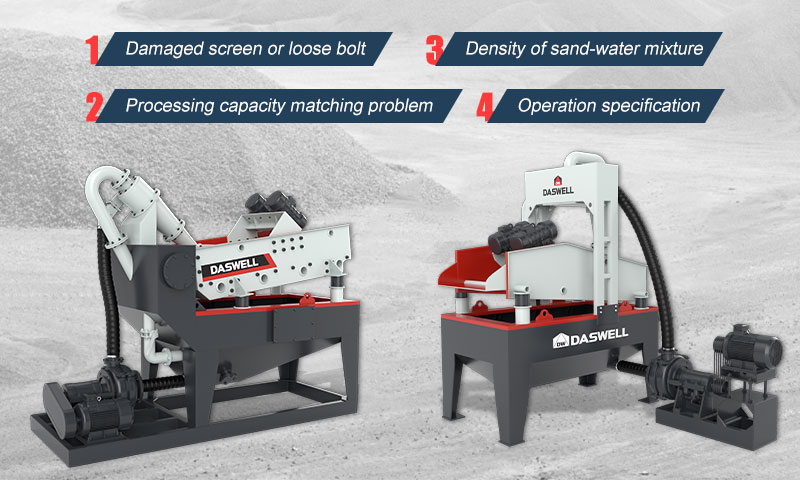

Damaged screen or loose bolts

If it is found that the amount of fine sand recovered is significantly reduced or there is sand leakage, the operator needs to check whether the screen is broken or the bolts fixing the screen are loose. In view of this situation, the solution is to replace the screen or tighten the bolts.

Matching of processing capacity

The power of the sand recovery machine should match the processing capacity of your own sand plant. Specifically, it is not advisable if the amount of waste water discharged from the sand plant is greater than the processing capacity of the sand recycling machine.

Sand water mixture density

The fine sand recycling machine can recover the fine sand in the sand-water mixture. If the density of the sand-water mixture is too large or too small, the recycling effect of the fine sand recycling machine cannot be truly achieved.

Operating Specifications

Operators need to undergo professional training to understand the composition, working principle and possible failures of the sand recycling equipment. As far as possible to find problems in advance, so as to avoid machine downtime to affect the recovery of fine sand.

Technical Data:

|

Model |

Feeding size (mm) |

Capacity (t/h) |

Spec. of screen(mm) |

Cyclone specs.(mm) |

Power (kw) |

Weight (kg) |

Overall dimension (mm) |

|

SRM250 |

≤10 |

20-50 |

900*1800 |

250 |

12.5 |

1400 |

3100*1300*2700 |

|

SRM300 |

≤10 |

40-80 |

900*1800 |

300 |

16.5 |

1500 |

3100*1300*2700 |

|

SRM350 |

≤10 |

60-100 |

900*1800 |

350 |

20 |

1700 |

3100*1300*2700 |

|

SRM550 |

≤10 |

40-100 |

1200*2400 |

250*2 |

26.4 |

2200 |

3600*1600*2800 |

|

SRM650 |

≤10 |

80-160 |

1200*2400 |

300*2 |

34.4 |

2500 |

3600*1600*2800 |

|

SRM750 |

≤10 |

120-200 |

1200*2400 |

350*2 |

41.4 |

2850 |

3600*1600*2800 |

|

SRM900 |

≤10 |

120-250 |

1500*3000 |

300*3 |

49.4 |

3500 |

4600*1900*2600 |

Model

Feeding size (mm)

Capacity (t/h)

Spec. of screen(mm)

Cyclone specs.(mm)

Power (kw)

Weight (kg)

Overall dimension (mm)

SRM1530-65

≤10

30-60

1500*3000

300*2

36

3750

3300*5250*3000

SRM1842-75

≤10

40-80

1800*4200

350*2

48

5860

4600*5560*3520

SRM1842J-100

≤10

60-100

1800*4200

250*4

59

6120

4600*5560*3520

SRM2442J-120

≤10

100-150

2400*4200

300*4

82

8520

4600*6560*3600

SRM2442J-140

≤10

100-150

2400*4200

350*4

96

8680

4600*6560*3600

SRM3048J-140

≤10

120-200

3000*4800

350*4

104

10800

5400*7000*4200

SRM3060J-180

≤10

120-200

3000*6000

300*6

127

12830

6600*7000*4200

SRM3660J-180

≤10

150-250

3600*6000

300*6

134

16500

6600*7000*4800