Types of gantry cranes

Single girder gantry crane

- The single girder gantry crane is mainly composed of the mast, the lifting trolley, the trolley running mechanism, the driver's cab and the electrical control system.

- The gantry is a box-shaped single main beam and two-legs structure. When the lifting capacity is less than 20t, the trolley adopts the vertical reverse roller type, and when the lifting capacity is greater than 20t, the trolley adopts the horizontal reverse roller type and runs on one side of the main beam.

- The main girder adopts the form of a single girder partial rail, and the outrigger and the lower beam form an L shape. Generally, there are cantilevers on both sides of the outrigger, which has a strong cross-span capacity when lifting objects and facilitates the transfer of objects from within the span to under the cantilever.

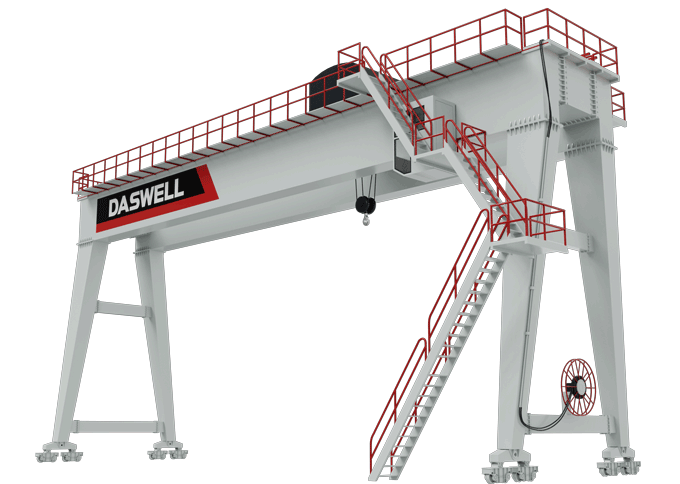

Double girder gantry crane

- The gantry crane is mainly used for bridge construction and consists of a gantry, hoist trolley, trolley running mechanism, driver's cab and electrical control system.

- The portal frame is a truss structure, which has the advantages of light structure and strong wind resistance, including the main beam, upper end beam, outriggers, lower end beam, traveling trolley and walking platform railings, etc.

- The main beam adopts a triangular truss structure, on which a track is laid for the trolley to move laterally along the direction of the main beam. The outriggers come in two forms, box-shaped or steel pipe.

- The trolley is arranged with a winch and is compact and lightweight.

Characteristics of gantry crane

- There are three modes of operation: ground handle, wireless remote control and driver's cab;

- Power supply is available in the form of cable reels and high-altitude slide wire;

- Select the high-quality steel, with high strength, light weight and not easy to deform;

- Solid base, small footprint, small dimensions above the track surface, and fast running;

- It is mainly composed of gantry (main beam, outriggers, lower beam, etc.), lifting mechanism, operating mechanism and electric control part. The electric hoist is used as the lifting mechanism, and it runs along the lower flange of the main beam I-beam during work;

- The gantry structure is divided into two types: box shape and truss. The box shape has good craftsmanship and is easy to manufacture; the truss has light weight and strong wind resistance;

- Modular design, short design cycle, high degree of generalization, improve the utilization rate of parts;

- Compact structure, small size, large working range, effectively improve production efficiency;

- Full frequency conversion control, stable operation, no impact, slow speed under heavy load, fast speed under light load, energy saving and consumption reduction.