What is a mobile concrete plant?

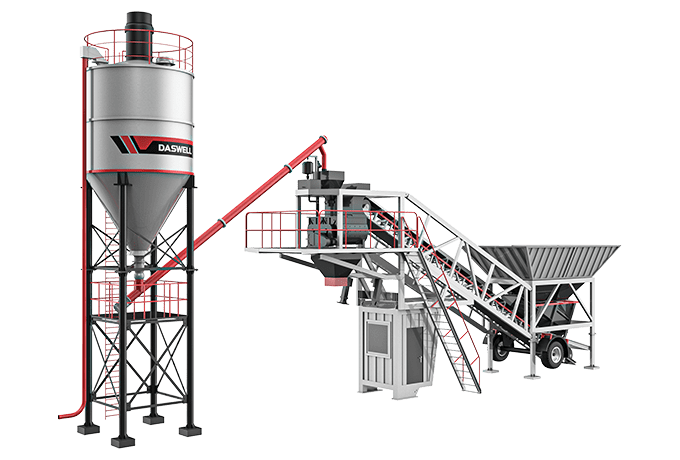

Mobile concrete batching plant is a portable, efficient and reliable concrete production equipment. It is a plant that concentrates the storage, weighing, conveying, mixing, discharging and fully automatic control system of raw materials on a mobile frame. The mobile batching plant can produce concrete in bulk at any site. And we offer mobile mixing plants with production capacity from 25m3/h to 100m3/h, which can be easily transferred with just one trailer when changing sites. The portable concrete batch plant is suitable for projects with short construction period and little demand for concrete.

What is the benefit of the mobile batching plant?

The biggest benefit that a mobile concrete mixing plant can bring to you is to produce concrete at the construction site. The pumping equipment can then transport the produced concrete directly to the pouring site, saving the cost of concrete transportation. The mobile ready mix concrete plant saves a lot of time and labor cost for the customer compared to the fixed plant, while ensuring the demand of concrete production.

Moreover, the workflow, operation and maintenance of the mobile batching plant for sale is basically the same as those of the stationary type plant. In particular, the mobile cement plant has the advantages of flexible movement and easy assembly and disassembly.

Features of mobile concrete batching plant

- Portable concrete plant can be installed and put into operation quickly.

- It is easy to maintain and move, and the small mixing plant can be transported with just one or two trailers.

- The structure of the mobile concrete plants are modular, which is easy to assemble and quick and convenient to install.

- You don't need to lay the foundation in advance before using the mobile cement batch plant. You only need to harden the ground or lay a layer of concrete, which greatly saves the cost of laying the foundation.

- The mobile concrete plant for sale is coated with special material, which has excellent rust resistance and is not easy to rust.

- The whole plant is made of ultra-high toughness steel plate, which is long-lasting and wear-resistant.

- PLC control system can achieve intelligent control of the entire workflow.

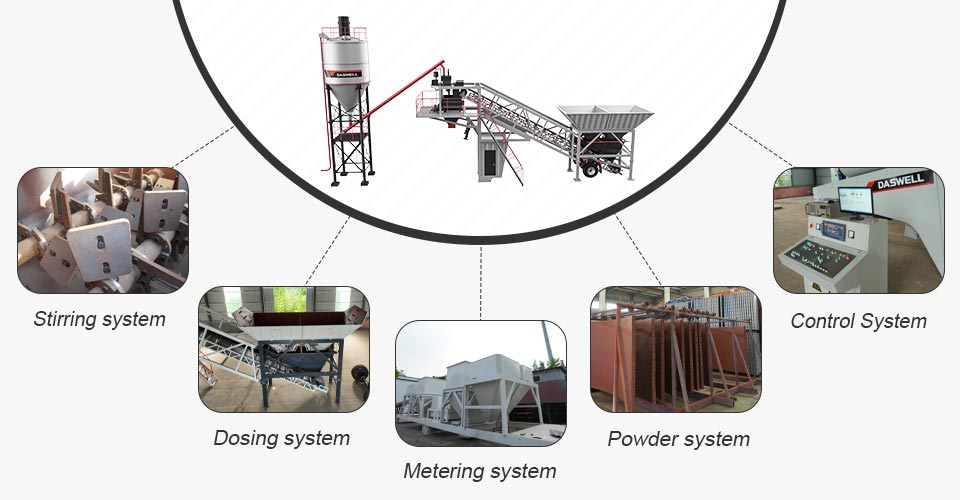

Components of mobile batch plant

Mixing system

Mobile concrete batching plants are usually equipped with twin shaft concrete mixer. Daswell offers its own brand or Sicoma twin shaft mixer machine for its customers. Of course, we can also provide planetary concrete mixers according to customer's requirements.

Batching system

The batching system is mainly composed of storage hopper, weighing hopper and belt conveyor.

Weighing system

It is mainly composed of cement weighing, water weighing, additive weighing, etc. The sensor of weighing system adopts the domestic famous brand LITIAN sensor, and the powder butterfly valve adopts the brand of SICOMA.

Feeding system

Adopt inclined belt for loading, shorten the loading length and save space.

Powder system

The powder system includes cement silo and screw conveyor.

Pneumatic control system

It is used to provide air supply to the individual discharge door cylinders.

Automatic control system

The main electrical components are selected from Schneider brand. The fully automatic control system can remotely manipulate the software, which can immediately assist customers to solve the problem remotely once it occurs.

Mobile concrete batching plant price

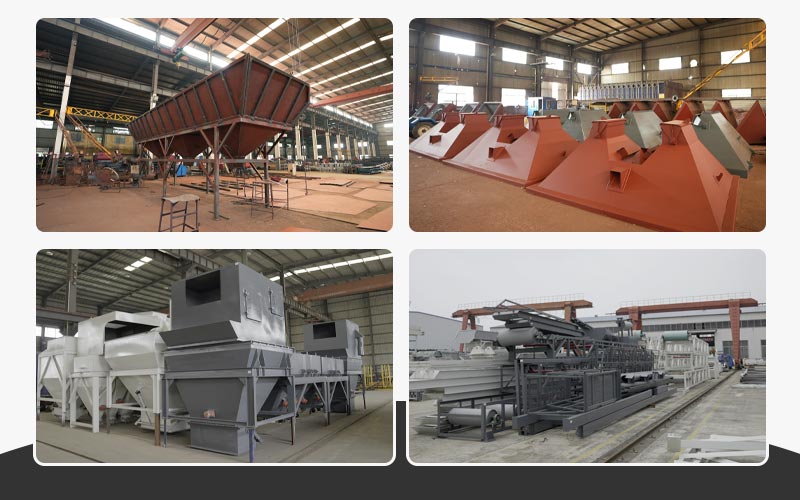

Daswell machinery are welcomed by customers for their high quality and outstanding durability. We have been committed to providing customers with reliable and convenient solutions to achieve efficient concrete production.

Every part of Daswell mobile concrete batch plant is famous brand at home and abroad. Moreover, our equipment undergoes strict manufacturing and factory testing, so you can trust us completely.

The mobile batching plant price varies with the production capacity and product configuration. So the exact cost will depend on your production requirements, for example, how many cubic meters of concrete do you need to produce per hour? Tell us your project requirements and we will provide you with a solution and price list as soon as possible, so come and contact us!

Mobile concrete batch plant manufacturers

Daswell has been specialized in manufacturing and exporting concrete mixing plant for more than 30 years, and has been committed to providing perfect solutions for customers according to their needs. Our service is always available, including technical consultation, quotation, product delivery, spare parts supply, trouble-shooting and repair, etc.

In addition, we have branches in many countries to help you solve technical problems and deliver vulnerable parts in time. Our portable batch plant can be installed and disassembled quickly, thus reducing the cost of moving and relocation. Its flexibility and other advantages of the mobile plants provide the perfect solution to complex problems.

If you are looking for a cost-effective solution to a practical construction problem, please feel free to call us!

Technical Data:

|

Model |

MCBP25 |

MCBP35 |

MCBP50 |

MCBP75 |

MCBP100 |

|

|

Capacity (m3/h) |

25 |

35 |

50 |

75 |

100 |

|

|

Concrete mixer |

Model |

TCM500 |

TCM750 |

TCM1000 |

TCM1500 |

TCM2000 |

|

Mixing power (kw) |

18.5 |

30 |

18.5×2 |

30×2 |

37×2 |

|

|

Output per batch (m3) |

0.5 |

0.75 |

1 |

1.5 |

2 |

|

|

Max. aggregate size |

≤60/80 |

≤60/80 |

≤60/80 |

≤60/80 |

≤60/80 |

|

|

Aggregate bin (m3) |

2×8 |

2×8 |

4×8 |

4×8 |

4×10 |

|

|

Walking speed (km/h) |

20 |

20 |

20 |

20 |

20 |

|

|

Weighing accuracy |

Aggregate |

±2% |

±2% |

±2% |

±2% |

±2% |

|

Cement |

±1% |

±1% |

±1% |

±1% |

±1% |

|

|

Water |

±1% |

±1% |

±1% |

±1% |

±1% |

|

|

Additive |

±1% |

±1% |

±1% |

±1% |

±1% |

|

|

Discharge height (m) |

3.8 |

3.8 |

4.0 |

4.0 |

4.0 |

|

|

Total power (kw) |

40 |

55 |

75 |

105 |

135 |

|