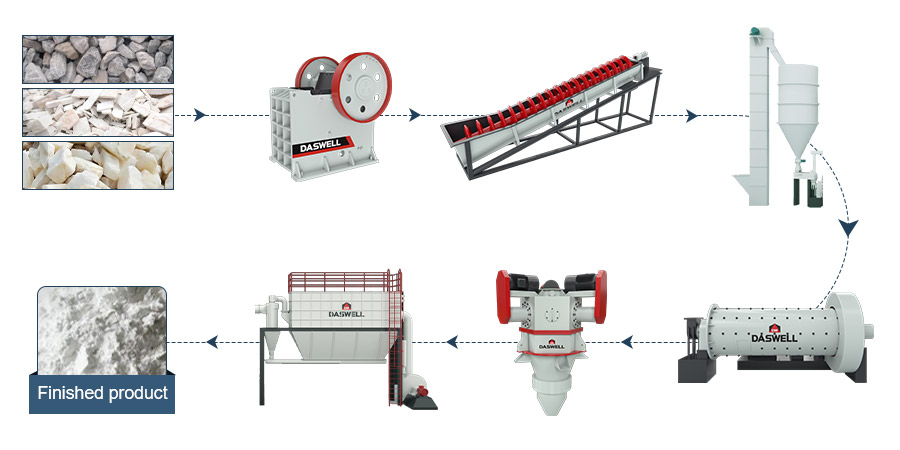

In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials. The calcium carbonate production line is mainly composed of crushers, screw conveyors, storage bins, grinding mill, dust collectors, classifiers and other equipment. The grinding mill is the core of the entire production line.

The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers. This article will provide you with some suggestions.

Production method of calcium carbonate powder

Before choosing a grinding mill, you need to understand how calcium carbonate is produced. At present, there are two main methods, dry grinding method and wet grinding method.

The dry grinding method is mainly used in primary grinding, and is suitable for the production of powders that do not require high particle size distribution.

The wet method uses coarsely crushed products as raw materials, and then adds solvents and related additives for regrinding. At the same time, by removing impurities in the ore, the fineness and purity of the finished product will be improved.

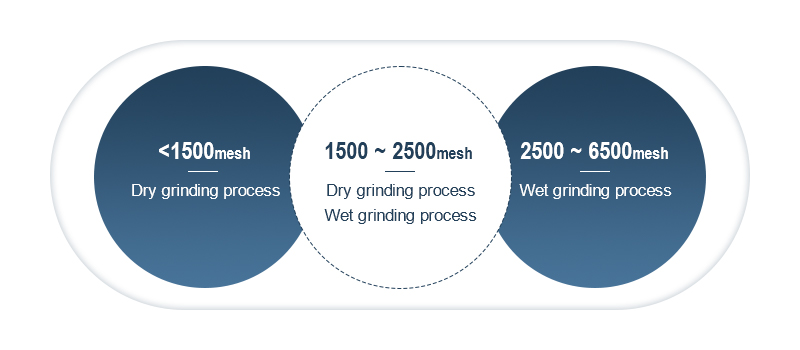

Generally speaking, the finished product size below 1500 mesh is generally produced by dry grinding process.

For product size from 1500 to 2500 mesh can be produced by dry gridning process or wet gridning process.

For products from 2500 to 6500 mesh, wet grinding process is usually appropriate for production.

|

Ground calcium carbonate |

Dry grinding process |

Wet grinding process |

|

Advantages |

Low equipment cost and mature industrial production; It is easy to control production conditions, adjust process parameters, and produce products with different requirements; Final products with special requirements can be modified after production. |

Large-scale continuous production; The finished product can reach high fineness, which can meet the production of some special requirements. The produced slurry has the advantages of high solid content, low viscosity and good dispersibility; It can meet the needs of different customers and produce high-quality ground calcium carbonate. |

|

Disadvantages |

It is generally mostly primary crushing, and the finished particles are relatively large. |

Large equipment cost and high operating costs; The finished product is difficult to transport and suitable for local use. |

Factors to consider when choosing the calcium carbonate gridning mill

Raw materials

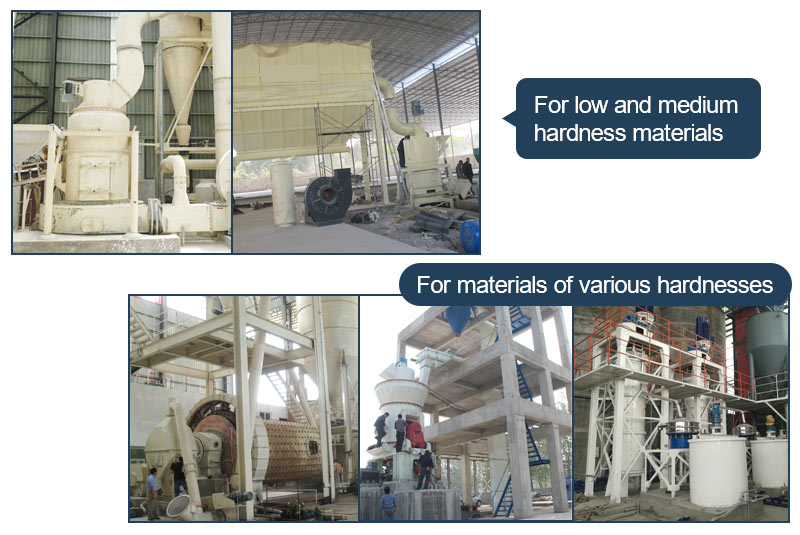

Different raw materials have different hardness. The hardness of the material suitable for different grinding mills is also different. Our common calcium carbonate grinding mills include ball mill, micro powder roller mill, Raymond roller mill, vertical mill, wet grinding mill and so on.

Raymond roller mill and micro powder roller mill are generally suitable for materials with medium and low hardness. Ball mills, vertical mills and wet grinding mills are generally suitable for materials of various hardness. Only by choosing the right grinding mill can its production efficiency be maximized.

Feeding and discharging size

Before choosing a grinding mill, you need to know the size of your material and the size of the finished product you need, so that you can choose a suitable mill.

|

Equipment |

Feeding size |

Discharging size |

|

Ball mill |

0-4mm |

5-45μm |

|

Micro powder roller mill |

0-10mm |

5-45μm |

|

Raymond roller mill |

25-35mm |

45-180μm |

|

Vertical mill |

0-40mm |

3-45μm |

|

Wet grinding mill |

About 45μm |

0-5μm |

Its capacity

You need to know roughly how much powder you need per day or year. Knowing this factor is to consider the configuration of the machine. If a single machine cannot meet your production needs, you need to consider using two or more mills.

Taking the wet grinding mill as an example, two parallel wet grinding mills can greatly increase the output per unit time of the production line; while two series wet grinding mills can improve the fineness of the finished product.

The shape and quality of the finished product

For some non-metallic minerals, such as graphite, talc, kaolin, wollastonite, etc., maintaining the particle shape of flakes or needles helps to improve their application performance and use value. For some downstream industries, it is better for the finished product to be spherical or close to spherical.

Therefore, the particle shape is also taken into consideration when selecting the grinding mill equipment for these minerals. Generally, the shape and quality of the finished ball mill will be better.

Energy consumption of equipment

Energy consumption is also an important factor to consider when selecting the calcium carbonate grinding mill, as it is an important component of equipment cost.

For common grinding equipment, the energy consumption of ball mill and wet grinding mill is relatively large; the energy consumption of Raymond mill, micro powder roller mill and vertical mill is relatively small.

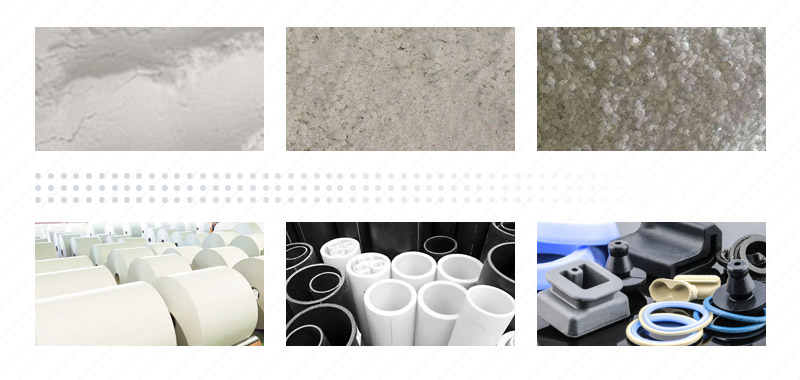

Applications

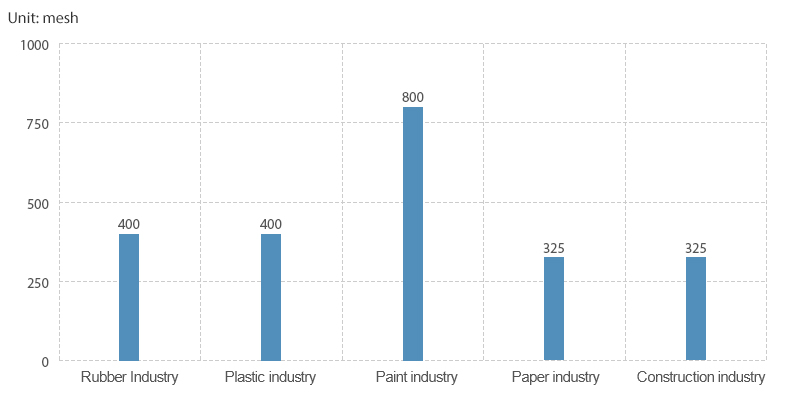

Different industries have different requirements in the process of using ground calcium carbonate powder. Take the following industries as examples:

- The rubber industry requires 400 mesh, which is mainly used for filling materials, reducing costs, and enhancing its strength and wear resistance;

- The plastic industry requires 400 mesh, which is mainly used to enhance its stability and enhance the smoothness of the surface.

- The paint industry requires 800 mesh, and the main function is to ensure that the filling amount is more than 30%;

- The paper industry requires 325 mesh, and the main function is to ensure the strength and whiteness of the paper, and the cost is low;

- The construction industry requires 325 mesh, and the main function is to increase the toughness and strength of the product.

Input costs

The initial investment cost and the late return on investment are one of the issues that customers are very concerned about before purchasing equipment. According to the above factors, first select the equipment suitable for your project, and then consider their prices and compare the prices of different manufacturers.

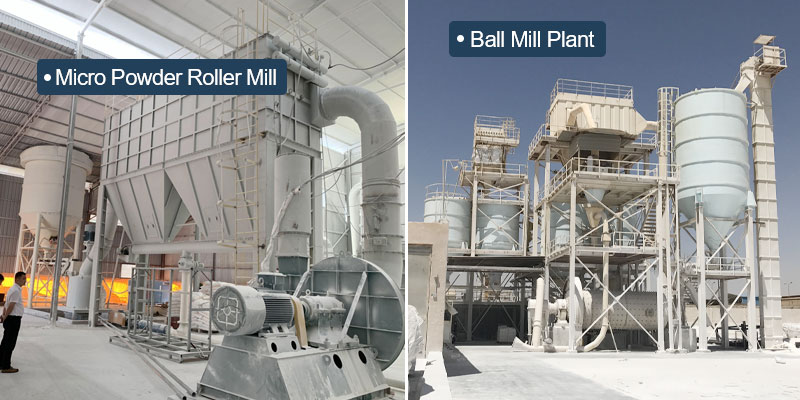

If you need to grind fine powder, but your budget is not too high, then you can consider choosing a micro powder roller mill. Similarly, if you need to grind fine powder, and you have sufficient budget and high quality requirements for the finished powder, then you can consider choosing a ball mill.

Characteristics of different grinding mills

Ball mill

Ball mills are often combined with classifiers to form a complete production line, mainly producing D97, 5 to 45μm ground calcium carbonate fine powder and ultrafine powder. Different models of ball mill host, its output is also different. Generally speaking, the annual output of the ball mill is between 10,000 tons and 200,000 tons.

Due to its advanced technology, good quality of finished products and stable operation, it has been well received by middle and high-end customers.

Micro powder roller mill

As the name suggests, the micro powder roller mill mainly crushes the material by rolling and grinding the multi-layer ring rollers. It is mainly used to produce ultrafine powder of 8-45μm.

Our common micro powder roller mill models have 21 rollers, 28 rollers and 34 rollers. The greater the number of grinding rollers, the greater its output.

Raymond roller mill

Raymond roller mills are mainly used to grind coarse powders. Its feed size is generally 25 to 30 mm, and the output size is 45 to 180 microns. Its passing rate is 99%, which is difficult for other grinding mill equipment. Moreover, it also has the characteristics of small footprint, convenient maintenance and low energy consumption.

Its output is generally 1 to 30 tons per hour (different finished product fineness will lead to different output). Raymond mill is widely used and welcomed by users all over the world.

Vertical mill

Vertical mill is a large-scale grinding equipment, which is widely used in cement, electric power, metallurgy, chemical and other industries. It is often used to produce powders as fine as 10 microns. The vertical mill has a large output and a small footprint.

Compared with the ball mill, although the powder produced by the vertical mill is not as good as the powder produced by the ball mill, the power consumption of the vertical mill is about 30% to 50% less than that of the ball mill. Therefore, the vertical mill is an ideal choice for customers who pursue low power consumption.

Wet grinding mill

Wet grinding mill, also known as ultra-fine stirring mill, is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, talc and other non-metallic minerals.

Its production process is relatively flexible, and it can be produced by a single unit or multiple units, and the material can be ground to 2000 to 8000 mesh or even finer. It has the characteristics of large output, high efficiency, low energy consumption and environmental protection.

|

Methods |

Equipment |

Finished product(D97/μm) |

Features |

|

Dry grinding process |

Raymond roller mill |

25-150 |

1.Applicable materials: medium and low hardness; 2.Product features: medium and low-end products, suitable for the production of coarse powder; 3.Energy saving; 4.High yield. |

|

Micro powder roller mill |

5-45 |

1.Applicable materials: medium and low hardness; 2.Product features: mid-end product, suitable for the production of fine powder; 3.Low energy consumption; 4.Long service life. |

|

|

Ball mill |

5-22 |

1.Applicable materials: Various hardness; 2.Product features: medium and high-end products, suitable for the production of fine powder; 3.The finished product is in good shape; 4.Stable and reliable operation; 5.High energy consumption. |

|

|

Vertical mill |

10-45 |

1.Applicable materials: Various hardness; 2.Product features: medium and high-end products, suitable for the production of fine powder; 3.High yield; 4.Energy saving and emission reduction. |

|

|

Wet grinding process |

Wet grinding mill |

0-5 |

1.Applicable materials: Various hardness; 2.High precision and fineness of finished products; 3.Flexible production line composition; 4.High energy consumption. |

Unit conversion table

When it comes to grinding related processes and equipment, it is indispensable to deal with the particle size of the material, and the fineness of the material in the mining industry is usually expressed by mesh. The number of meshes refers to the number of holes on the screen per inch, and 50 mesh means that the number of holes per inch is 50. The larger the mesh number, the finer the material particle size; the smaller the mesh number, the larger the material particle size.

Many customers may not know what is the relationship between our common mesh, micrometer and millimeter. The following conversion table is for your reference:

|

Mesh number |

Micrometer |

Millimeter |

|

100mesh |

150μm |

0.15mm |

|

200mesh |

74μm |

0.074mm |

|

325mesh |

45μm |

0.045mm |

|

400mesh |

38μm |

0.038mm |

|

600mesh |

23μm |

0.023mm |

|

800mesh |

18μm |

0.018mm |

|

1250mesh |

10μm |

0.01mm |

|

1750mesh |

8μm |

0.008mm |

|

2500mesh |

5μm |

0.005mm |

|

5000mesh |

2.5μm |

0.0025mm |

|

8000mesh |

1.6μm |

0.0016mm |

If you have any questions about choosing a calcium carbonate grinding mill, please feel free to communicate with us!