7 Mga Hakbang upang Matulungan Kang Bumuo ng isang Kapaki-pakinabang na Concrete Batching Plant

Para sa ilang mga tagagawa na nais mamuhunan sa kongkreto batching plant, Bago mag-invest, Karamihan sa kanila ay nais na maunawaan ang buong proseso ng pagtatayo ng isang kongkretong planta at ang mga bagay na nangangailangan ng pansin.

Dahil mula sa paggawa ng pananaliksik sa merkado at pagpili ng site sa maagang yugto, Pagpili ng modelo at pagsasaayos ng kongkreto na halaman, Pagpapanatili at Pamamahala sa Huling Yugto, Ang lahat ng ito ay nangangailangan ng maraming paghahanda at desisyon mula sa mga namumuhunan. Kung mayroong isang buong proseso na dapat isaalang-alang, Makakatulong ito sa mga namumuhunan na makagawa ng mas angkop na desisyon.

Ang artikulong ito ay pag-aayos ng buong proseso ng pagtatayo ng isang kongkretong batching plant mula sa pitong aspeto.

Pananaliksik sa merkado & Pagsusuri

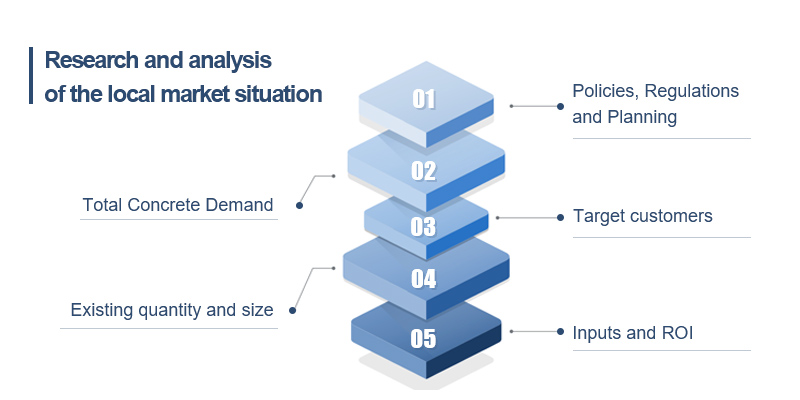

Bago ka magpasya na mag-invest, Kailangan mo munang magsaliksik at suriin ang sitwasyon ng lokal na merkado. Kabilang dito ang:

- Pag-unawa sa mga lokal na patakaran at regulasyon sa kongkretong industriya, pati na rin ang pagpaplano ng konstruksiyon ng imprastraktura sa mga nakaraang taon;

- Upang matantya ang kabuuang lokal na pangangailangan para sa kongkreto;

- Alamin kung sino ang iyong mga target na customer;

- Alamin ang bilang at sukat ng umiiral na lokal na komersyal na kongkreto batching plant;

- Suriin ang iyong sariling personal na pondo at isaalang-alang ang iba't ibang mga pamumuhunan sa maagang yugto at ang pagbabalik sa pamumuhunan ng buong proyekto sa huling yugto.

Ang mga salik na ito ay magbibigay sa iyo ng isang komprehensibong pag-unawa sa lokal na merkado, At maaari kang magpasya sa laki ng kongkreto na paghahalo ng planta na nais mong mamuhunan batay sa iyong base ng customer at ang pangangailangan para sa kongkreto.

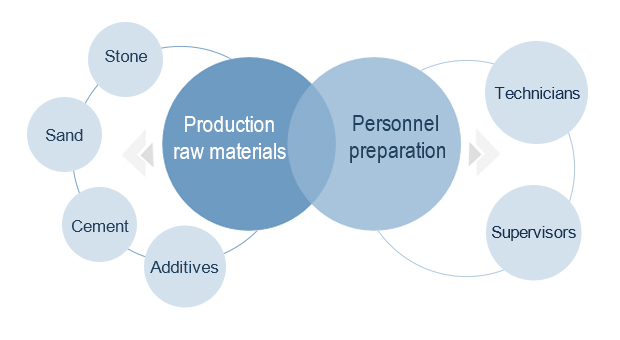

Kaugnay na paghahanda ng mapagkukunan

Ang pangunahing hilaw na materyales na ginagamit sa paggawa ng kongkreto ay bato, buhangin, semento, Mga Additives, atbp. Kaya, Sa maagang yugto, Kailangan mong makahanap ng isang mahusay na tagapagtustos ng mga hilaw na materyales at ihambing ang kalidad at presyo ng mga hilaw na materyales mula sa iba't ibang mga tagagawa. Iyon ay dahil ito ang magpapasiya sa kalidad ng kongkreto na iyong ginawa at ang iyong gastos.

Bukod pa rito, Magtatag ng iyong sariling mga channel ng pagbebenta para sa komersyal na kongkreto at gumawa ng isang mahusay na synergy sa pagitan ng upstream at downstream na industriya.

Pagkatapos ay kailangan mong mag-recruit ng naaangkop na tauhan. Kailangan mong magrekrut ng mga bihasang technician at superbisor. Bagama't ang karamihan sa mga kongkretong halaman ng paghahalo ngayon ay awtomatikong kinokontrol, Kailangan mo pa rin ng mga propesyonal para sa pagtatakda ng mga kongkretong ratio at pangangasiwa ng buong daloy ng trabaho. Maaari kang lumikha ng isang propesyonal na koponan ng iyong sariling kumpanya.

Piliin ang lokasyon ng iyong kongkretong planta

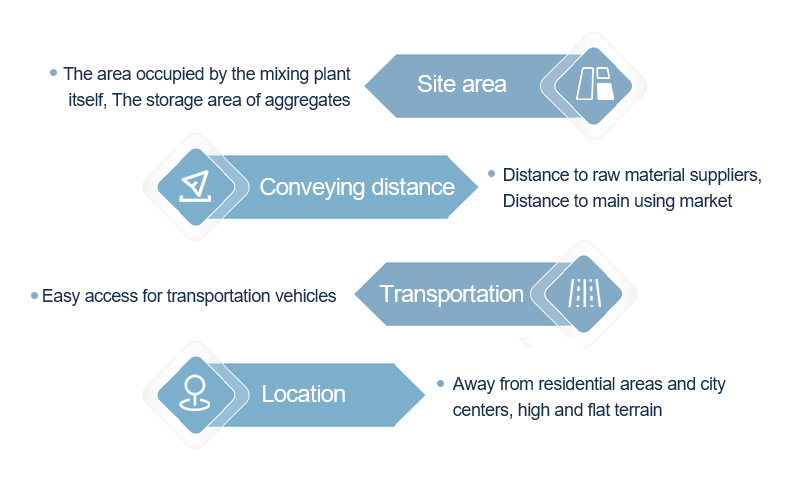

Ang pagpili ng site ng kongkreto batch plant ay isa ring napakahalagang isyu. Dapat mong isaalang-alang ang mga kadahilanan tulad ng lugar ng site, distansya ng transportasyon at sitwasyon ng trapiko.

Kapag isinasaalang-alang ang lugar ng site, Bilang karagdagan sa lugar na inookupahan ng kongkreto na paghahalo ng planta mismo, Espesyal na pansin ay dapat bayaran sa stacking area ng aggregates. Ang produksyon ng kongkreto ay kailangang kumonsumo ng isang malaking halaga ng buhangin at graba na pinagsama-sama, Kaya't ang pinagsama-samang lugar ng stacking ay dapat na sapat na malaki upang matugunan ang mga pangangailangan ng pagkonsumo ng produksyon.

Kasama sa distansya ng paghahatid ang parehong distansya mula sa kongkretong halaman hanggang sa supply ng hilaw na materyal at ang distansya mula sa kongkretong halaman hanggang sa pangunahing paggamit ng merkado. Sa pangkalahatan, Ang pinakamahusay na distansya ng paghahatid para sa isang trak ng panghalo ay tungkol sa 15km.

Bukod pa rito, Kinakailangan na ganap na isaalang-alang kung ang trapiko sa paligid ng kongkretong batch plant ay maginhawa at kung maginhawa para sa mga sasakyan ng transportasyon na pumasok at lumabas.

Bilang karagdagan, Ang lugar ay dapat piliin nang malayo sa mga residential area at sentro ng lungsod hangga't maaari upang mabawasan ang polusyon sa lungsod. Gayundin, Isaalang-alang ang pangangailangan ng paagusan, Ang site ay dapat piliin sa isang mataas at patag na lugar hangga't maaari upang maiwasan ang malubhang epekto sa produksyon kapag ang tubig ay naipon sa panahon ng malakas na ulan.

Pagpili ng kongkreto batching plant

Kapag pumipili ng isang kongkreto batching plant, Hindi mo lamang dapat isaalang-alang ang modelo nito, kundi pati na rin ang kaugnay na configuration nito.

Piliin ang modelo ng kongkreto batch plant ayon sa laki ng scale ng produksyon:

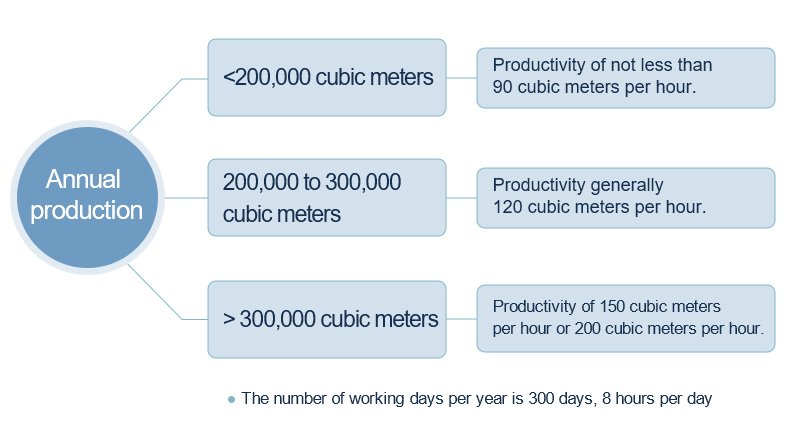

- Ang taunang produksyon ay mas mababa kaysa sa 200,000 metro kubiko, at ang pagiging produktibo ng kongkreto na planta ay karaniwang hindi bababa sa 90 metro kubiko bawat oras;

- Para sa isang taunang output ng 200,000 sa 300,000 metro kubiko, Sa pangkalahatan, ang produktibo ng konkretong planta ay 120 metro kubiko bawat oras;

- Ang taunang produksyon ay higit pa sa 300,000 metro kubiko, at ang pagiging produktibo ng kongkreto na planta ay pangkalahatang 150 sa 200 metro kubiko bawat oras;

- Ang bilang ng mga araw ng trabaho na kinakalkula dito ay 300 Mga araw sa isang taon at 8 Mga oras sa isang araw;

- Kung ang iyong proyekto ay nangangailangan ng isang konkretong dami ng 70 metro kubiko bawat oras, Pagkatapos ay dapat kang pumili ng isang kongkreto na halaman na may isang teoretikal na rate ng produksyon ng 90 Metro kubiko bawat oras sa halip na 75 metro kubiko bawat oras. Ito ay dahil ang aktwal na rate ng produksyon ng isang kongkretong planta ay karaniwang mas mababa kaysa sa maximum na teoretikal na rate ng produksyon.

Mayroon ding pagsasaayos ng kongkreto na paghahalo ng planta upang isaalang-alang.

Ang kongkreto na panghalo ay ang core ng buong kongkreto na halaman, Kapag pumili ka ng isang mixer, Dapat mong suriin kung ang tatak ng kongkreto na panghalo na na-configure ng tagagawa ay maaasahan. Kung mayroon kang mga espesyal na pangangailangan, Maaari mo ring hilingin sa tagagawa na i-configure ang iba pang mga sikat na tatak ng mga mixer para sa iyo, halimbawa, ang mixer ng SICOMA.

Bilang karagdagan, Dapat mo ring i-configure ang semento silo na may tamang output ayon sa dami ng semento at ang batching machine na may tamang bilang ng mga bins ayon sa uri at proporsyon ng mga aggregates.

Pagpili ng mga sumusuporta sa kagamitan

Upang matiyak ang maayos na operasyon ng buong kadena ng produksyon at pagbebenta, Kailangan mo ring bumili ng ilang mga kagamitan sa pantulong, halimbawa, Mga Wheel Loader, kongkreto panghalo trak, kongkreto na bomba, kongkreto reclaimer, atbp.

Sa pangkalahatan, Ang halaman ng paghahalo ay nilagyan ng kagamitan 1 o 2 Mga Loader, Pangunahing ginagamit upang pakainin ang batching machine.

Dapat din itong i-set up 10 sa 20 Mixer trak ng higit pa sa 8 metro kubiko (Alisin ang taba mula sa tiyan taba taunang 300,000 Cubic meters bilang isang halimbawa) Upang ihatid ang natapos na kongkreto sa site ng customer. Ang bilang ng mga trak ng panghalo ay malapit na nauugnay sa distansya ng transportasyon at output ng kongkreto.

Siyempre, Maaari mo ring isaalang-alang ang pagbili ng ilang kongkretong kagamitan sa pagbomba at pag-upa ng mga ito sa mga customer na bumili ng iyong kongkreto ngunit walang kagamitan sa pagbomba. Maaari rin itong magdagdag ng dagdag na kita sa iyong pangkalahatang proyekto, dahil marami pa ring mga customer na nangangailangan ng pag-upa ng kongkreto na kagamitan sa pagbomba.

Bilang karagdagan, Maaari mo ring isaalang-alang ang pagdaragdag ng isang kongkretong reclaimer. Pangunahin itong ginagamit upang maghiwalay, Kolektahin at muling gamitin ang buhangin, bato at putik sa basura matapos linisin ang mixer truck. Maaari nitong epektibong malutas ang problema ng kongkretong polusyon at makatipid ng mahalagang mga mapagkukunan ng materyal na gusali.

Isaalang-alang ang layout ng site

Kapag nagpaplano ng site ng konstruksiyon, Kailangan mong isaalang-alang ang layout ng kongkreto na paghahalo ng halaman, Pagpapanatili ng Concrete Plant, Transportasyon ng Sasakyan, at mga pangangailangan sa pangangalaga sa kapaligiran.

- Ang iba't ibang mga pinagsama-samang pinagsama-sama ay dapat na pinaghiwalay ng mga pader, at ang mga materyales na ginagamit ay dapat na naka-imbak nang hiwalay mula sa mga bago upang maiwasan ang paghahalo. Bukod pa rito, Ang lupa ng bakuran ng buhangin at graba ay dapat patigasin upang mapadali ang paglo-load ng mga wheel loader at upang maiwasan ang mga labi tulad ng putik mula sa pagpasok sa materyal.

- Karamihan sa mga materyales sa kongkretong batching plant ay dinadala ng malalaking sasakyan, Kaya't kinakailangan na tiyakin na ang mga sasakyan ay tumatakbo nang maayos at hindi makagambala sa isa't isa. Ang pinakamainam na solusyon ay ang paggamit ng dalawang pintuan para sa mga papasok at papalabas na materyales. Ang pangunahing kalsada sa site ay dapat na malawak, Dapat ay nakalaan ang espasyo para sa mga malalaking sasakyan na lumiko at gumawa ng U-turn.

- Ang isang tiyak na pag-access ay dapat na nakalaan sa paligid ng mga pangunahing bahagi ng kongkreto na paghahalo ng planta upang mapadali ang pagpapanatili sa ibang pagkakataon.

- Ang buong site ng konstruksiyon ay dapat na isang hilig na eroplano, lalo na, Ang ibabaw ng kalsada ay dapat magkaroon ng isang tiyak na dalisdis upang matiyak na ang tubig ulan ay maaaring mabilis na dumaloy. Kung ito ay nasa isang patag na kalsada, Magkakaroon ng tubig sa kalsada. Pagkatapos ng pag-iipon ng tubig, Mas madaling lumubog ang kalsada sa ilalim ng paggulong ng mga mabibigat na sasakyan, Bumubuo ng isang mabisyo na bilog, at ang kalsada ay masisira sa maikling panahon.

- Bumuo 1 o 2 Siguraduhin na may sapat na tubig ang mga ito upang malinis ang makina. Ang pangunahing mixer machine at mixer truck ay dapat linisin kaagad pagkatapos ng trabaho upang maiwasan ang pinsala sa makina na sanhi ng kongkreto solidification.

Bilhin at i-install ang iyong kongkretong planta

Matapos makumpleto ang mga paunang paghahanda, Maaari mong isaalang-alang ang paghahanap ng tamang tagagawa ng kongkreto na halaman. Online man o offline, Makakakita ka ng maraming mga tagagawa ng batching plant. Ang pinakamahusay na paraan upang makahanap ng isang maaasahang tagagawa ay upang bisitahin ang kanilang opisina at pabrika, ngunit, Dahil ang mga tao ngayon ay apektado ng epidemya, Ang paglalakbay ay lubos na pinaghihigpitan, Paano Makipag-usap sa Online Upang Malaman ang Lakas ng Isang Tagagawa?

Una sa lahat, Maaari kang mag-browse sa website ng tagagawa upang makita ang kanilang mga produkto, Balita sa Pagpapadala at Kaugnay na Pagpapakilala ng Kumpanya. Matapos maunawaan kung ang mga produktong inaalok nila ay kung ano ang kailangan mo, Maaari mo munang makipag-ugnay sa kanila para sa karagdagang komunikasyon tungkol sa mga detalye ng pagsasaayos at mga presyo ng mga produkto. Makipag-usap sa mga kawani ng pagbebenta, Hindi mo lamang mahuhusgahan kung sila ay propesyonal o hindi, ngunit tingnan din kung ang kanilang paglilingkod ay maingat at taos-puso.

Gayundin, Maaari kang makakuha ng isang mas detalyadong pag-unawa sa tagagawa na ito sa pamamagitan ng ilang iba pang mga platform, tulad ng, Facebook, Youtube, Linkedin, atbp. Siyempre, Ang serbisyo na ibinibigay ng tagagawa ay isa ring mahalagang kadahilanan na dapat mong isaalang-alang. Sa wakas, Bumili ng isang kongkreto batching plant mula sa isang tagagawa na sa tingin mo ay malakas at maaasahan.

Tungkol sa Pag-install, Pag-aayos at Pagpapanatili ng Concrete Plant, Pangkalahatang nagsasalita, Ito ang serbisyong ibinibigay ng tagagawa. Kaya, Kung naghahanap ka para sa isang tagagawa ng konkreto na halaman na mas malapit sa iyo, Mas magiging maginhawa para sa kanila na ibigay sa iyo ang kaukulang mga serbisyo.

Kung mayroon ka pa ring anumang mga katanungan tungkol sa konstruksiyon ng kongkreto batching plant, Maligayang pagdating sa pakikipag-ugnay sa amin para sa karagdagang komunikasyon!