In sand production line, especially in wet sand production line, sand washing is an essential part in order to improve the quality of finished sand, and sand washing machine is needed for sand washing.

The sand washing machine can wash away the soil and impurities on the surface of the sand, and at the same time destroy the water vapor layer covering the sand, so as to facilitate dehydration, play the role of efficient sand washing and cleaning, and improve the quality of the finished sand.

There are different types of sand washing machines, all of which have their own characteristics and scope of application. So how to choose a suitable sand washing machine? This article will introduce you from several aspects.

Types of sand washing machine

The common types of sand washing machines on the market include spiral sand washing machines and impeller sand washing machines.

Spiral sand washing machine

The spiral sand washing machine mainly stirs the sand and gravel through the spiral device in the equipment, so that the sand and gravel are mixed with water. Then the sand and gravel are gradually screened under the action of the spiral, and discharged from the discharge port, thus realizing the cleaning and screening effect of the sand and gravel. In terms of type, it can be divided into two types: single-spiral sand washer and double-spiral sand washer.

It is mainly suitable for washing, grading and impurity removal in metallurgy, building materials, hydropower and other industries, especially suitable for construction sand and road construction sand.

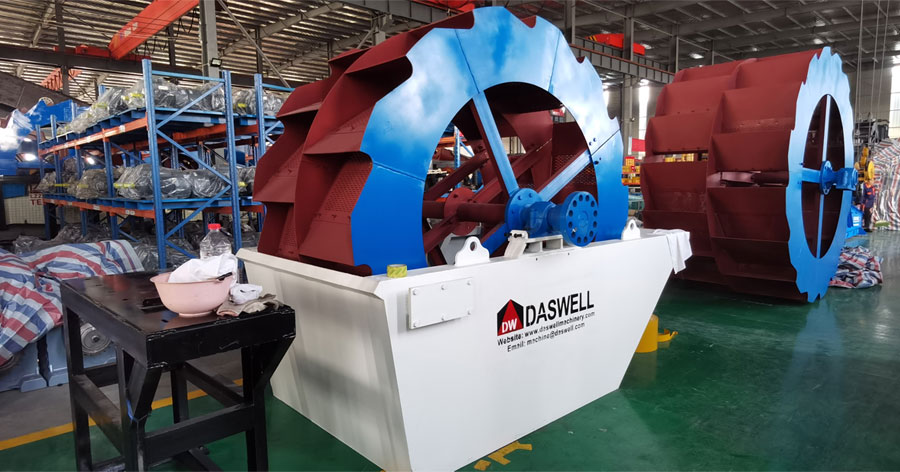

Impeller sand washing machine

Impeller sand washer is claso called wheel bucket sand washing machine. The sand and gravel in the wheel bucket sand washing machine are turned over under the drive of the wheel bucket, and grind each other to remove impurities on the surface. At the same time, add water to the inside of the sand washing machine to form a strong water flow, and take away the washed out impurities and other foreign objects with small specific gravity in time. The clean sand and gravel are taken away by the blades and poured into the discharge tank trough from the rotating impeller, thus completing the cleaning of the sand and gravel. It mainly includes single-row wheel bucket, double-row wheel bucket and three-row wheel bucket sand washing machine.

It often forms a high-quality sand production line together with a sand making machine, which is used in transportation, chemical industry, mining, water conservancy and hydropower and other fields.

Difference between spiral sand washer and impeller sand washer

Appearance structure

The overall structure of the wheel bucket sand washing machine is relatively simple. There are fewer wearing parts in the equipment, and after the installation is completed, its occupied area is small. In order to reduce the phenomenon of bearing damage caused by water, sand and pollutants, the wheel type sand washing machine has designed a structure in which the impeller drive bearing device is isolated from water and sand, thereby greatly reducing the failure rate of the equipment.

The spiral sand washer has a slender body and a horizontal structure, which makes the structure simpler. But it is not as convenient as the wheel sand washer in the installation arrangement.

Applicable material particle size

The wheel bucket sand washer is generally used to clean materials of about 5mm. And the spiral sand washing machine can not only clean the large size of the stone, but also the smaller size of the material.

The loss of sand and gravel

The wheel bucket sand washing machine consumes less water during the sand washing process, and the loss of fine sand and stone powder is small, so that the sand grade and fineness modulus of the washed sand and gravel can meet the standard requirements.

In comparison, the sand and gravel loss of the spiral sand washing machine is relatively large during the sand washing process.

Cleanliness of the washed sand

The cleanliness of sand washing refers to the quality of finished sand after washing.

During the cleaning process, the sand and gravel in the spiral sand washing machine are turned over and cleaned more times, and the cleaning is more thorough, so the quality of the finished sand and gravel is better.

Cleaning capacity

The cleaning capacity of the spiral sand washing machine is relatively strong, and it can effectively clean the sand with serious mud impurities. It is often used in large-scale sand production lines.

The production capacity of the wheel sand washer is smaller than that of the spiral sand washer, so it is more suitable for small and medium-sized sand production lines.

Water consumption

The wheel bucket sand washing machine does not need to use too much water during the sand washing process, and the loss of fine sand is small.

However, the water consumption of the spiral sand washing machine is relatively large, and the sand and gravel are lost more.

Price

The price of the wheel bucket sand washer is relatively low, and the operating cost is also low, which belongs to the type of economical and efficient sand washer. The price of the spiral sand washer is relatively high, which belongs to the high-end sand washing machine.

If your project requires a small output, you can choose a wheel bucket sand washer. However, the transportation cost of the large-capacity wheel sand washer is relatively high, so if your project requires a large-capacity machine, you can choose a spiral sand washer.

How to choose a right sand washing machine?

Choosing the right sand washing machine requires comprehensive consideration of the following aspects.

First of all, it is necessary to consider which sand washing machine to choose. If you compare the sand washing effect between the spiral sand washer and the impeller sand washer, it should be considered in combination with the actual production situation.

The spiral sand washing machine has high efficiency, large processing capacity, and relatively clean sand washing, but it consumes a lot of water and loses more fine sand. The output of the impeller sand washing machine is relatively low, but the water consumption is small, the loss of fine sand is less, and the price is cheaper than the spiral sand washing machine.

Therefore, if the sand and gravel to be cleaned have a large particle size, a spiral sand washing machine can be selected. If the budget cost is low or the project scale is relatively small, you can choose the impeller sand washing machine.

Second, look for a trustworthy manufacturer. Whether online or offline, you can find many manufacturers of sand washing machines. You can learn more about manufacturers through their websites, social media accounts, etc. You can also visit their factories and offices offline to learn about the production process of the equipment. In this way, comprehensively evaluate the strength of the manufacturer to ensure that you can buy a high-quality sand washing machine.

The price of the equipment is also a very important factor. You can get quotes from different manufacturers online to choose the most economical one. However, when buying a sand washing machine, you can't just pay attention to the price and choose the manufacturer with the lowest quotation. That's because the lowest price can mean a lower-quality product. This will cause you to invest more in maintenance costs during use.

Then, you also need to find out from the manufacturer what kind of after-sales service they can provide. If the equipment needs to replace wearing parts, can they be sent to the construction site in time? If the sand washing machine breaks down, can their engineers come to repair it? Good after-sales service can ensure the normal operation of your equipment and shorten the downtime caused by failure.

Finally, find out what your customers are saying. If most customers are satisfied with a manufacturer's equipment and their services, it means that the manufacturer is trustworthy. If half or more of the customers who have a bad opinion of the manufacturer, you'd better not choose to cooperate with such a manufacturer, otherwise it may cause you certain economic losses.

How to configure the sand washing production line?

Sand and gravel materials mainly include two types, natural sand and artificial sand. Different types of sand require different sand washing production lines.

If your raw material is natural sand, such as river sand, sea sand, etc., your production line configuration should be like this (the following production line is for reference only, when actually configuring the sand washing production line, you need to comprehensively consider various factors).

If you want to produce artificial sand, sand washing machine is not enough, you also need a series of sand making equipment. There are many types of raw materials that can be used to produce machine-made sand, such as river pebbles, limestone, granite, basalt, etc. According to the different raw materials, the configuration of the sand making production line is also different. The line configurations provided below are for reference only.

If the sand is fine, a fine sand recovery machine can be added, otherwise the sand that is too fine will be washed away during the sand washing process. This will not only cause serious loss of finished products, but also affect the gradation of sand, resulting in unreasonable gradation and large fineness modulus, which greatly reduces the quality of machine-made sand. Excessive discharge of fine sand will also cause environmental pollution.

So in this case, you need to add a fine sand recycling machine after the sand washing machine to recover the fine sand lost from the sand washer. This can not only reduce loss, but also realize the effective utilization of sand and gravel resources.

If you need to configure a sand washing production line, please feel free to consult us. We have professional engineers to customize the suitable sand washing production line for you!