Halaman ng pagdurog ng bato

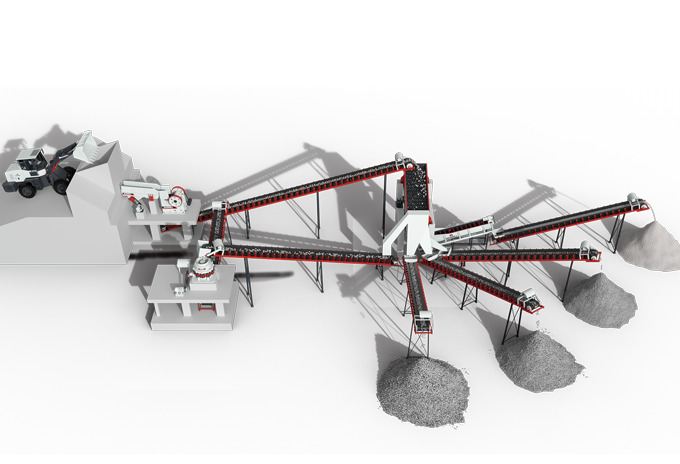

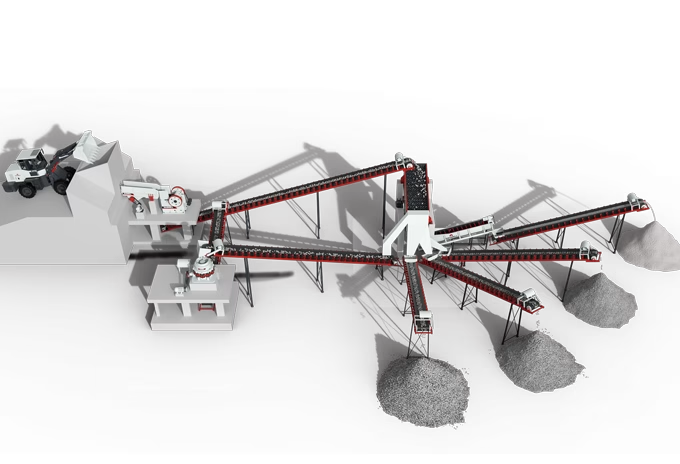

The stone crushing plant is a special equipment used to produce sand and gravel aggregates used in construction, highways, railways, mining and other industries.

Generally speaking, a crushing plant is an entire production line composed of different equipment such as jaw crusher, cone crusher, sand making machine, vibrating screen, and belt conveyor.

Makipag-ugnayan sa aming lokal na koponan sa Pilipinas sa +63 915 802 0960for personalized assistance and a fast quote!

Stone crushing plant is also called aggregate crushing plant or rock crushing plant. It is a set of facilities, which is designed for processing large rock, boulders, and stones into smaller sizes. You can use it in construction, road building, mining, and other industries in Philippines.

Daswell mainly has two types of crushing plant for you to choose. The stationary crushing plant is fixed installation. It is popular in large quarries and long-term projects. For your convenient relocation, there are also mobile type crushing plants for your projects. We have wheel type mobile crusher plants and crawler-type for your different requirements in Philippines.

If you want to know more about the stone crushing plant. You can Makipag-ugnay kay Daswell in Philippines. We have different solutions for you. You can choose the most suitable crushing plant solution for your own projects.

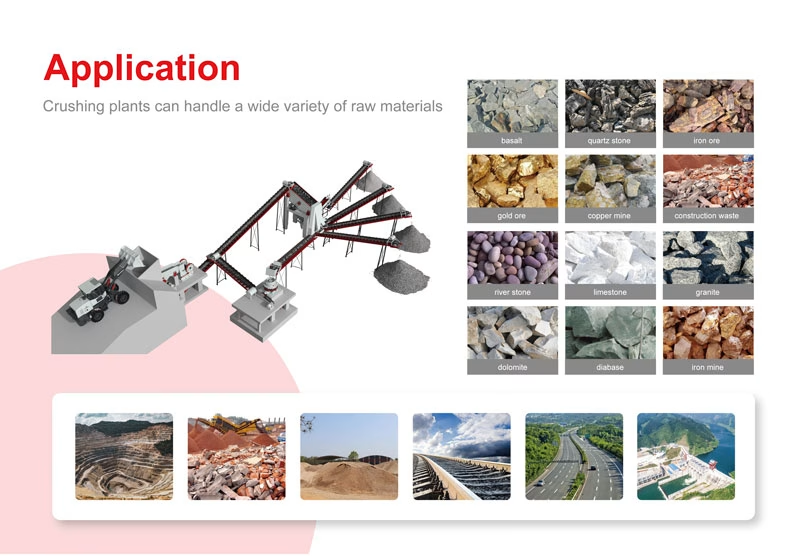

What materials are available for crushing by using Daswell crusher plant in Philippines?

They are primary raw materials for producing gravel, sand, and crushed stone. For instance, the granite can be crushed for making high-strength concrete, road base, an so on. Crushed basalt is often used for asphalt mix, construction aggregates, etc.

| Material Type | Hardness (Mohs Scale) | Common Uses |

|---|---|---|

| Granite | 6–7 | High-strength concrete, road base, railway ballast |

| Basalt | 5–6 | Asphalt mix, construction aggregates, erosion control |

| Limestone | 3–4 | Cement production, agricultural lime, road base |

| Sandstone | 4–6 | Building facades, decorative gravel, paving |

| Marmol | 3–5 | Decorative chips, terrazzo flooring, landscaping |

| Quartzite | 7 | Manufactured sand (M-sand), high-strength concrete |

| Gneiss | 6–7 | Road construction, railway ballast |

Stone crushing plants can also process demolition waste and industrial byproducts for recycling. Whether for the concrete debris in demolition sites or asphalt pavement materials in road repairing sites, the stone crushers are applicable.

| Material | Pinagmulan | Recycled Use |

|---|---|---|

| Concrete Debris | Demolition sites | Recycled aggregates for new concrete |

| Asphalt Pavement | Pagkukumpuni ng kalsada | Reused in new asphalt mixes |

| Bricks & Tiles | Old buildings | Crushed for road sub-base or landscaping |

| Slag (Steel/Iron) | Metallurgical plants | Road base, cement additive |

Under special cases, there are some materials, which needs specific crushers because of their properties. For example, the soft chalk, needs impact crushers. And the coal is more suitable for using hammer crushers.

| Material | Challenges | Recommended Crusher |

|---|---|---|

| Tisa | Too soft, dusty | Impact crusher (low abrasion) |

| Karbon | Brittle, dusty | Double-roll crusher or hammer mill |

| Gypsum | Soft, moisture-sensitive | Jaw crusher + hammer crusher |

Where you can use the Daswell stone crushing plant in Philippines?

Mining and quarrying: Daswell stone crushers plant can process waste rock into usable materials. You can also produce aggregates for mine infrastructure, such as roads and platforms.

Construction production: For your Philippine concrete production, you can using our stone crushing plant for making crushed stones. And then mixing them with cement for producing concrete. And if you are a brick maker, the crushing plant is also useful. The crushed fine aggregates can improve the strength and durability of the bricks. Whether you are a concrete maker or brick maker, Daswell in Philippines can provide you not only stone crushing plant, but also concrete machines at brick making machinery.

Road and highway construction: For the base the sub-base layers, the crushed stones can provide stability. Especially, for your Philippine road pavement business, the crushing plant is key as well. The crushed aggregates can bind with bitumen for road surfaces.

3 types of Daswell stone crushing plants for your Philippine projects

According to different output capacities, applications and the mobility. There are three types of crushing plants in Philippines for your reference.

Stationary pagdurog ng halaman

The stationary crushing plant adopts fixed installation. It has high output capacity. It has higher working efficiency and stable production for large volumes. You can use it for mining and quarrying, or some large infrastructure projects in Philippines.

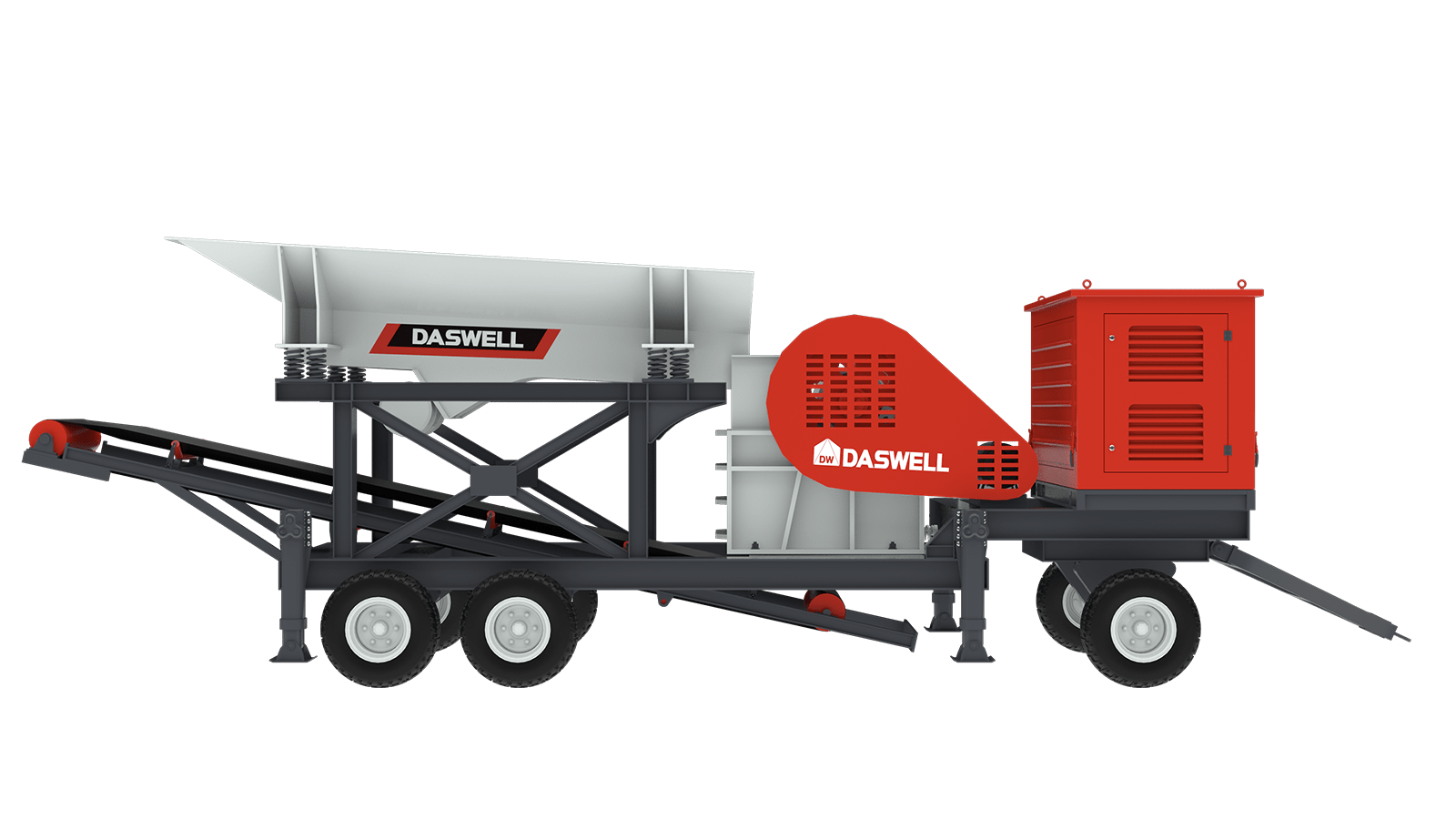

Mobile pagdurog ng halaman

For the mobile type crushing plant, we have wheel type mobile crusher and crawler type mobile crushing plant. They can move between job sites. If you want to start a temporary project or multiple locations, the mobile crushing plants will be suitable. It do not need foundation. And it is ideal for urban construction and demolition recycling.

Mini portable mobile crusher plant

This type of mobile crusher has compacter crushing unit. It is easy to transport. You can tow it conveniently. For your small projects, remote sites, or some tight spaces, the small portable crushing plant is a good choice.

Whether you want to buy crushing plant for your small, medium, or large scale projects in Philippines, Daswell can meet your needs. Both the stationary and mobile plants, we can provide you high quality machines at factory prices. Especially, we have branches in Philippines, Indonesia, Egypt, Mexico, Malaysia, etc. You can get local service for better business running.

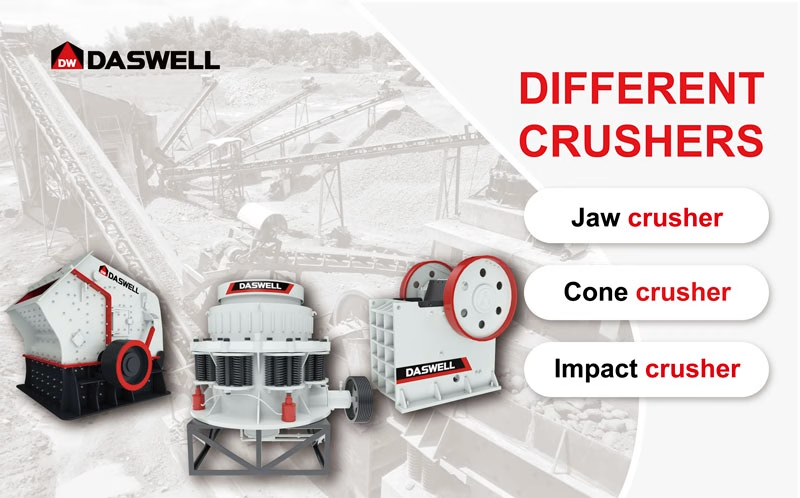

Daswell various equipment configurations for your stone crushing plant

When you considering a stone crushing plant in Philippines, there are some factors, which will determine the plant equipment configurations. For example, different material hardness require different crushers. And the finished particles shape requirements also influence the equipment configurations. Here you can know some tips when you considering the crushing plant configurations.

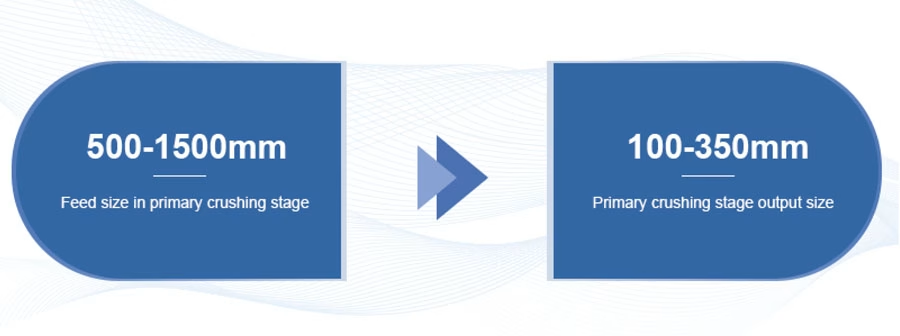

Primary crushing machine

The primary crushing process is mainly used for reducing bulk raw materials to manageable sizes. Generally, the feeding size is 500mm to 1500mm. And the discharge size will be 100mm to 350mm. You can use our jaw crusher or gyratory crushers.

Ang Mga pandurog ng panga has simple structure with low cost. And it is reliable for hard materials. It utilizes compression via fixed and movable jaw plates.

Ang gyratory crusher machine is high efficiency. And it allows large sizes materials. For your large-scale mining, it is an ideal choice. This crusher machine utilizes rotary crushing action in a vertical chamber.

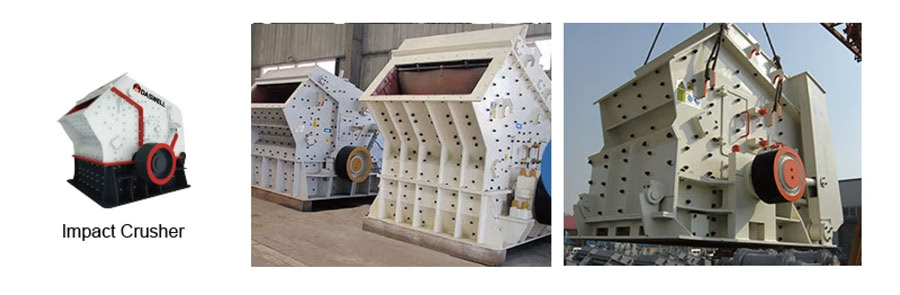

Secondary and tertiary crushing machine

The secondary and tertiary crushing can further reduce the particle size for specific applications. The secondary crushing processes 350mm-100mm to 100mm-40mm. And the tertiary crushing machine can reduce the 100mm-40mm to 30mm-10mm.

Ang kono pandurog at Mga pandurog ng epekto are commonly used in this process. Kono pandurog machine is more suitable for medium and hard rocks. IF you materials is brittle, the impact crushing machine will be more suitable.

Sand making and shaping machine

This is final size adjustment. This process can achieve precise particle shape. And you can use it for concrete or asphalt. The feeding size should under 40mm and the discharging size will be 0 to 10mm.

Daswell has vertical shaft impact crusher. You can also call it sand maker. This machine can process granite, river pebbles, tailings into high-quality, well-shaped aggregates for construction.

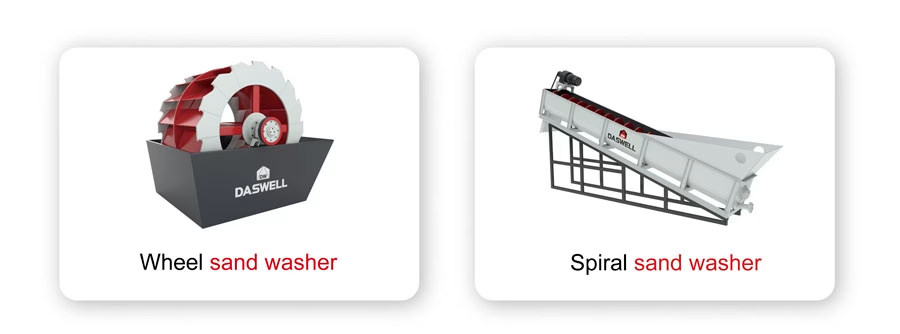

Sand washing machine

This machine can purify the aggregates quality. It will remove the impurities, such as clay, dust, improving the aggregate quality.

There are two types of sand washers for you in Daswell. The spiral sand washer can clean fine materials with screw agitation. And the wheel bucket sand washers can wash efficiently with rotating buckets. Meanwhile, it can save more water than the spiral type.

Contact Daswell for getting the most suitable crushing equipment configurations in Philippines.