Tahanan » Paggiling Mills

Paggiling Mills

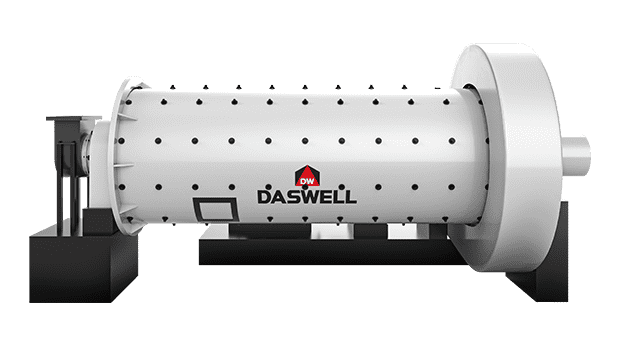

Grinding mills are mainly used to grind raw materials into calcium carbonate powder.

Daswell grinding mills mainly include a ball mill and classification production line, roller mill, Raymond mill, and so on.

Paggiling Mills makinarya at kagamitan

Mahusay na mga solusyon sa paggiling para sa isang malawak na hanay ng mga materyales

Mills para sa Fine at Ultrafine Powder Processing

Grinding mills are essential equipment for industries such as mining, construction, chemicals, and non-metallic mineral processing. They help to grind bulk materials such as limestone, calcium carbonate, barite, talc, quartz, and dolomite into fine or ultrafine powders that meet specific size and purity requirements.

Daswell offers a wide range of grinding solutions to meet different materials, capacities, and end-use goals. Our main products include ball mills for large-scale coarse grinding and several types of vertical roller mills for precision powder production.

Vertical roller mills refer to advanced grinding systems that use rotating rollers pressed against fixed rings or tables to grind materials under pressure. This type of equipment includes Raymond mills and ring roller mills, which are widely used for non-metallic minerals with a Mohs hardness of less than 7. These mills are ideal for obtaining fine powders ranging from 50 mesh to 2500 mesh, and have higher energy efficiency and lower dust emissions than traditional methods.

Whether you need a stable 325 mesh output or ultra-fine powders below 10 microns, Daswell mills offer customizable configurations, stable performance, and automated control. Our solutions have won the trust of the global market for their superior quality, reliability, and long service life.

Comparison of 3 Grinding Mills

|

Feature / Type |

Ball Mill |

Ring Roller Mill |

Raymond Mill (Raymond Roller Mill) |

|---|---|---|---|

|

imahe |

|

|

|

|

Prinsipyo ng Pagtatrabaho |

Epekto at paggiling sa pamamagitan ng mga bola ng bakal sa loob ng isang umiikot na drum |

Maramihang mga roller pindutin ang materyal laban sa isang nakapirming paggiling singsing |

Ang mga nakabitin na roller ay pinindot ng sentripugal na puwersa papunta sa paggiling ng singsing |

|

Istraktura |

Horizontal rotating cylinder with grinding media (steel balls) |

Patayong istraktura na may maramihang mga roller mahigpit na pagpindot sa singsing |

Patayong istraktura na may 3-5 pendulum na nakabitin na mga roller ng paggiling |

|

Angkop na Mga Materyales |

Various hard or medium-hard ores, metallic minerals, limestone, cement clinker |

Non-metallic minerals: heavy calcium, talc, gypsum, quartz, calcite, dolomite, etc. |

Non-metallic minerals: calcium carbonate, talc, gypsum, feldspar, limestone, etc. |

|

Sukat ng Pagpapakain |

≤25mm (≤50mm for some large models) |

≤10mm |

≤20mm |

|

Sukat ng Output |

Usually above 75μm (80–200 mesh) |

5–45μm (325–2500 mesh) |

50–325 mesh, some models up to 400 mesh |

|

Kontrol sa Fineness |

Ayusin sa pamamagitan ng bilis o sistema ng salaan |

Ayusin ang bilis ng classifier at daloy ng hangin |

Adjust analyzer speed, airflow, and roller-ring clearance |

|

Pagkonsumo ng Enerhiya |

High (mainly impact and friction-based) |

Low (compression-based grinding) |

Medium (compression-based grinding) |

|

Kapasidad |

High, suitable for large-scale production |

Medium to high, ideal for ultra-fine powder production |

Medium, suitable for small to medium production lines |

|

Kahirapan sa pagpapanatili |

High: frequent wear of liners and steel balls |

Low: Wear parts like rings and rollers are durable |

Medium: rollers and rings require regular replacement |

|

Mga Tipikal na Aplikasyon |

Cement plants, mining, metallurgy, and coarse grinding in beneficiation lines |

Fine powder processing, non-metallic mineral industries |

Medium-fineness powder applications in chemicals, construction materials, fillers, etc. |

|

Puwang sa sahig |

Malaki |

Katamtaman |

Maliit hanggang katamtaman |

|

Kabaitan sa kapaligiran |

Mahina - nangangailangan ng karagdagang mga sistema ng pagkolekta ng alikabok |

Mabuti - binabawasan ng selyadong sistema ang pagtagas ng alikabok |

Average - nangangailangan ng fan at dust removal system |

How to Choose the Right Grinding Mill?

High output demand + suitable for metal ores or cement plants: Choose Ball Mill

Pursuing ultra-fine powder + non-metallic minerals + energy efficiency: Choose Ring Roller Mill

Medium fineness + versatile applications + lower investment cost: Choose Raymond Mill

Makipagsosyo sa Daswell para sa mas matalinong mga solusyon sa paggiling

At Daswell, we understand that every production line is unique and your material processing goals are different. With decades of experience in manufacturing and exporting high-performance grinding equipment, we can provide customized solutions to meet your required fineness, capacity, and material type. Whether you are upgrading an existing system or starting a new project, our team of experts will support you from consultation to installation and beyond.

Email: today for a personalized quote or technical consultation. Let’s work together to create a more efficient future.