Tahanan » Mga Kongkreto na Mixer » Nakatigil na Concrete Batching Plant

Nakatigil na Concrete Batching Plant

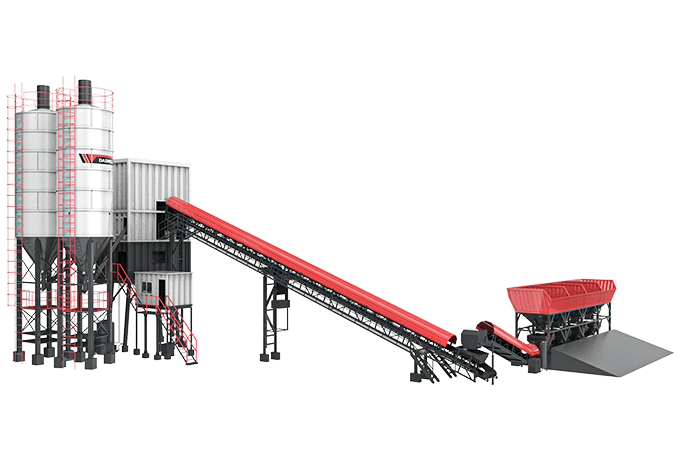

A stationary concrete batching plant is a concrete production facility with a high degree of mechanization and automation.

It uses precise weighing and mixing technology to ensure the quality of concrete production. The stationary concrete plant is divided into two forms: skip hopper stationary concrete batching plant and belt conveyor stationary concrete batching plant.

A stationary concrete batching plant is designed for large-scale, long-term projects requiring consistent, high-quality concrete production. Built for durability and efficiency, it is ideal for precast factories, industrial construction, and infrastructure projects.

It mainly includes mixing system, batching system, measurement system, feeding system, powder system and air control system. We can also customize for you according to your specific requirements. There are different configurations for you to choose. If you want to know more about the different configurations, you can Makipag-ugnay sa aming koponan.

Daswell various stationary concrete batching plant in Philippine site

Wide Applications of Stationary Concrete Batching Plant

Daswell stationary concrete batching plant has the advantages of large-scale centralized production, high performance, high production efficiency and good product quality. It is often used in various projects, which has a large amount of work, a long construction period and a concentrated construction site.

Roads and Highways – High-volume paving and structural concrete

Bridges and Tunnels – Precision-mixed concrete for load-bearing structures

Dams and Hydropower – Mass concrete production with strict durability requirements

Airports and Ports – High-strength concrete for runways and heavy-duty surfaces

Concrete Pipes and Hollow Core Slabs – Uniform mixing for prefabricated elements

Prefab Walls and Structural Components – Customizable mixes for factory production

RCC (Roller-Compacted Concrete) – Ideal for dams and industrial flooring

Commercial Concrete Supply – Steady production for construction companies

On-Site Batching for Developers – Cost-effective solution for large housing projects

Daswell stationary concrete batching plant has high output, the capacity can be 25-240 cubic meters per hour. And the PLC-controlled batching can realize precision and efficiency. If you want to buy a stationary concrete batching pant for your projects, send messages to us!

9 Key advantages of Daswell stationary Concrete batching plant

- High production capacity: It is designed for continuous operation with outputs ranging from 25m³/h to 240m³/h. It can meet your different project sizes requirements. And we can also customize for you. Our stationary concrete batching plant are equipped with twin-shaft horizontal mixers or planetary mixing machine. These two types of mixers are popular used in the batching plant. They can mix the concrete fast and homogeneously.

- Modular design for easy installation: The modular structure can realize quick and convenient installation. It is suitable for various job sites and regional conditions.

- Sturdy and long-lasting construction: There are heavy-duty steel structures ensures stability and longevity. Meanwhile, the reinforced aggregate bins and support frames can bear heavy loads.

- Precise batching and mixing systems: The advanced weighting system can measure the cement, aggregates, water and additives accurately. And the PLC control system are automated, error-free operation.

- Low maintenance and easy operation: We use imported components for ensuring the reliability. For the lubricating, the centralized lubrication system extends bearing and gear life.

- Versatile concrete production: It is suitable for RCC, dry concrete, wet-mix, precast, and ready-mix applications. We can also customize for your different projects needs.

- Environment friendly: The dust collection system minimizes airborne particles. And the noise-reducing design are compliance with environmental regulations.

- Customized configurations: It is optional for you to choose the cement silos, screw conveyors, admixture dosing systems.

- Advanced cleaning system: We adopt automatic high-pressure water pump for efficient cleaning. And you can choose the automatic or manual control.

Main Parts and Accessories of Stationary Concrete Batching Plant

Sistema ng paghahalo

Daswell usually uses twin-shaft mixers to mix ready-mixed concrete, and can also be equipped with vertical planetary mixers according to customer needs. According to customer needs, the twin-shaft mixer can use its own brand, or it can use the Sicoma brand twin-shaft mixer.

Sistema ng Batching

The batching machine of the stationary concrete mix plant is mainly composed of storage hopper, weighing hopper and belt conveyor. The batching system adopts Japanese SMC cylinder and Amcells Corp sensor.

Sistema ng pagsukat

It is mainly composed of cement measurement, water measurement, admixture measurement, aggregate measurement, fly ash measurement, etc. The sensor of the metering system adopts the Amcells Corp, and the powder butterfly valve adopts the Sicoma brand.

Sistema ng Pagpapakain

The bucket lift mixing plant lifts the aggregate directly into the mixer through the bucket. The belt-type mixing plant lifts the aggregate to the aggregate temporary storage hopper through the belt conveyor, and then discharges it into the mixer through the aggregate temporary storage hopper.

Sistema ng pulbos

The powder system of the stationary cement concrete batch plant includes cement silo and screw conveyor. The cement silo adopts the export bolted cement silo, which is convenient for packing and transportation. The cement silo is equipped with dust collector, safety valve, high and low material level gauge, air control box, butterfly valve, etc., all of which are of WAM brand. The screw conveyor can be equipped with our own screw conveyor, or with Sicoma or WAM.

Sistema ng kontrol ng hangin

The air control system of the stationary concrete batch mix plant provides air supply for each discharge door cylinder. Adopt Japanese SMC air control components. The air compressor adopts well-known domestic brands.

What is the Stationary concrete batching plant price?

With the development of urban construction, it is worth mentioning that the stationary concrete batching plants have great advantages. Their centralized mixing and commercial concrete supply has great markets. And the return on investment of the stationary concrete batching plant is high.

You can calculate according to the local price of concrete, sand and gravel, cement, water, and electricity. Use the income minus the cost of the investment to see how long it takes to pay for itself and make a high profit.

The price of Daswell stationary concrete batching plants on sale is different according to the different configurations. According to your different requirements, we can recommend for you.

For your reference, our smallest batching plant, whose production capacity is about 25 cubic meters of concrete per hour, the price is about 210,000RMB. If you have your specific requirements, please Makipag-ugnay sa aming koponan sa pagbebenta. And we will specially design for you and make your own quotation.

Different Configurations you can choose from Daswell for Stationary Batching Plant

Daswell after-sale Sevice for your Stationary Concrete Batching Plant Maintenance

24/7 After-Sales Support – Keeping Your Business Running

Free Investment Support – From Planning to Profit

For your stationary concrete batching plant purchasing requirements, we can provide you full set of service from selection to after-sales service. And we can also recommend you the best solutions according to your specific requirements. For your concrete batching projects, our company offers you mobile type concrete batching plants as well.

Meanwhile, we have many branches in many countries. You can also visit our local office for more details about our company and machines.

Are you considering getting a stationary concrete batching plant? Contact Daswell Team Now!

Technical Data:

| Modelo | CBP25 | CBP35 | CBP50 | CBP75 | |

| Capacity (m³/h) | 25 | 35 | 50 | 75 | |

| Tagahalo | JS500 | JS750 | JS1000 | JS1500 | |

| Pinagsama-samang Bin | PLD800 | PLD1200 | PLD1600 | PLD2400 | |

| Discharge Height (m) | 3.8 | 3.8 | 3.8 | 3.8 | |

| Cycle Time (s) | 72 | 72 | 72 | 72 | |

| Pagtimbang Katumpakan (%) | Pinagsama-sama | ±2 | ±2 | ±2 | ±2 |

| Semento | ±1 | ±1 | ±1 | ±1 | |

| Tubig | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | |

| Modelo | CBP60 | CBP90 | CBP120 | CBP180 | CBP240 | |

| Capacity (m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Tagahalo | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | |

| Pinagsama-samang Bin | PLD1600 | PLD2400 | PLD3200 | PLD4800 | PLD6400 | |

| Discharge Height (m) | 4 | 4 | 4 | 4 | 4 | |

| Cycle Time (s) | 60 | 60 | 60 | 60 | 60 | |

| Pagtimbang Katumpakan (%) | Pinagsama-sama | ±2 | ±2 | ±2 | ±2 | ±2 |

| Semento | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Tubig | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | ±1 | |